Mastering Hard-to-Find Electronic Components Sourcing for Modern Electronics

Winnie King

The Growing Challenge of Hard-to-Find Electronic Components Sourcing

In today’s fast-paced world of electronics manufacturing, securing reliable access to electronic components is more critical than ever. However, one of the most pressing issues facing engineers, product designers, and procurement teams is Hard-to-Find Electronic Components Sourcing. Whether due to global supply chain disruptions, rapid technological obsolescence, or sudden spikes in demand, many businesses struggle to obtain essential parts needed for their circuit board designs.

The complexity of modern electronics means that even a single missing component can delay entire production runs, increase costs, and damage customer relationships. This makes mastering the art and science of Hard-to-Find Electronic Components Sourcing not just a logistical necessity—but a strategic advantage.

From legacy systems requiring outdated ICs to cutting-edge devices depending on newly released chips with limited availability, the spectrum of challenges is broad. In this article, we’ll explore why certain components become difficult to source, examine proven strategies for overcoming these hurdles, and discuss how partnering with the right manufacturing partner can make all the difference.

Why Are Some Electronic Components So Difficult to Source?

Understanding the root causes behind component scarcity is the first step toward effective Hard-to-Find Electronic Components Sourcing. Several interrelated factors contribute to this growing challenge:

Global Supply Chain Disruptions

Events such as pandemics, geopolitical tensions, natural disasters, and trade restrictions have repeatedly exposed vulnerabilities in the global semiconductor and electronics supply chain. For example, factory shutdowns during the COVID-19 pandemic led to massive backlogs in chip production, affecting industries from automotive to consumer electronics.

Even minor disruptions at key fabrication plants—often located in concentrated regions like East Asia—can ripple across the globe. When lead times stretch from weeks to months (or even over a year), companies are forced into reactive sourcing modes, often turning to alternative suppliers or obsolete stock.

Component Obsolescence

Technology evolves rapidly, and manufacturers frequently discontinue older models to focus on newer, more efficient versions. This renders many previously standard components obsolete. In industries like aerospace, medical devices, and industrial automation, where equipment lifecycles span decades, finding replacements for discontinued parts becomes a recurring challenge.

Obsolescence management, often following standards such as IEC 62402, has therefore become a crucial aspect of Hard-to-Find Electronic Components Sourcing, especially when redesigning circuits isn’t feasible due to certification requirements or cost constraints.

High Demand and Low Supply Cycles

Emerging technologies such as electric vehicles, AI hardware, 5G infrastructure, and IoT devices have created unprecedented demand for specific components—particularly advanced microcontrollers, power management ICs, and memory modules. When demand outpaces supply, allocation systems kick in, favoring large-volume buyers over smaller enterprises.

This imbalance often forces design teams to seek alternatives through secondary markets or redesign products entirely—a time-consuming and costly process.

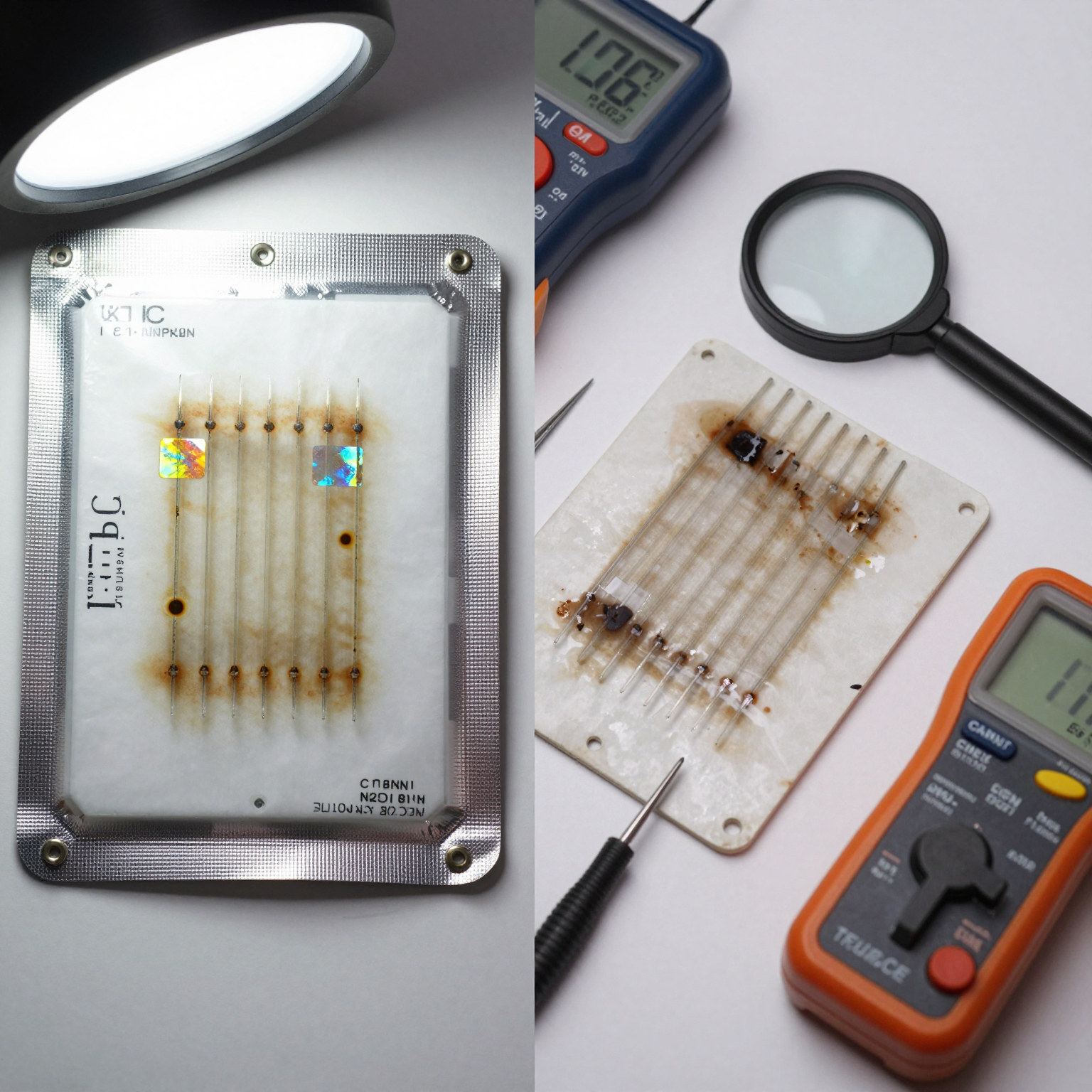

Counterfeit Risk in Secondary Markets

As primary channels dry up, many turn to independent distributors or brokers. While some operate legitimately, others sell counterfeit, recycled, or substandard components. These fake parts may pass initial inspections but fail prematurely in the field, leading to safety risks and reputational damage.

Thus, any strategy involving Hard-to-Find Electronic Components Sourcing must include rigorous verification processes to ensure authenticity and reliability. Organizations often reference ERAI databases to stay updated on high-risk suppliers and counterfeit part alerts.

Proven Strategies for Effective Component Sourcing

Successfully navigating the complexities of Hard-to-Find Electronic Components Sourcing requires a proactive, multi-pronged approach. Here are several strategies employed by leading electronics manufacturers:

1. Early Engagement with Suppliers

Engaging suppliers early in the design phase allows engineers to select components with stable supply chains and long-term availability. Designers should consult distributor databases (like Digi-Key, Mouser, or Arrow) during schematic development to check current stock levels, lead times, and lifecycle status.

Using tools like part lifecycle forecasting software can also help anticipate future obsolescence and guide component selection accordingly.

2. Design for Availability (DfA)

Design for Availability emphasizes choosing components based not only on technical specs but also on market availability and longevity. This includes:

- Selecting multiple compatible components (second sources)

- Avoiding overly specialized or custom parts unless absolutely necessary

- Using common package types that are easier to source and assemble

By building flexibility into the bill of materials (BOM), companies reduce dependency on any single component and improve resilience against shortages.

3. Strategic Inventory Management

Maintaining buffer stocks of critical components can protect against short-term supply fluctuations. While holding inventory increases upfront costs, it can prevent far greater losses caused by production stoppages.

Some companies use “lifetime buys” to purchase large quantities of soon-to-be-discontinued parts. However, this strategy requires accurate forecasting and proper storage conditions to avoid degradation.

4. Leveraging Authorized Distributors and Franchise Partners

Working exclusively with authorized distributors ensures traceability and reduces the risk of counterfeits. These partners often have direct relationships with original component manufacturers (OCMs) and better visibility into upcoming allocations and new product releases.

They may also offer services like kitting, BOM analysis, and cross-reference support—valuable assets in Hard-to-Find Electronic Components Sourcing efforts.

5. Exploring Alternative Components and Cross-Referencing

When a specific component is unavailable, identifying functional equivalents or pin-compatible substitutes can keep projects moving. Engineers can use parametric search engines to find parts with similar electrical characteristics, temperature ranges, and form factors.

However, thorough testing is required to validate performance under real-world conditions before approving substitutions.

The Role of Contract Manufacturers in Sourcing Success

Partnering with an experienced contract manufacturer (CM) can dramatically simplify Hard-to-Find Electronic Components Sourcing. A capable CM brings established supplier networks, bulk purchasing power, and deep expertise in supply chain logistics.

For instance, a full-service PCB assembly services provider often maintains long-standing relationships with both component vendors and alternative sourcing channels. They can quickly identify viable substitutes, verify authenticity, and manage procurement across complex BOMs.

Moreover, many CMs offer turnkey solutions that include complete electronic component sourcing, reducing the burden on internal teams. This integrated approach streamlines production, improves quality control, and accelerates time-to-market.

Tools and Resources for Tracking Component Availability

Several digital platforms and tools assist in monitoring and managing component availability:

- Octopart: Aggregates pricing and stock data from hundreds of distributors.

- FindChips: Offers real-time inventory searches across global suppliers.

- Ultra Librarian: Provides CAD models and sourcing insights.

- SiliconExpert and IHS Markit: Offer lifecycle and risk analysis for components.

These tools empower engineering and procurement teams to make informed decisions early in the design cycle, minimizing downstream delays.

Additionally, subscribing to industry newsletters, attending trade shows, and joining professional forums can provide early warnings about potential shortages or upcoming discontinuations.

Case Study: Rescuing a Delayed Medical Device Launch

Consider a medical device company developing a next-generation patient monitor. Midway through prototyping, they discovered that a key analog front-end (AFE) sensor was marked as “not recommended for new designs” by the manufacturer.

Facing potential delays and costly redesigns, the team engaged a contract manufacturer with strong parts procurement capabilities. The CM identified a functionally equivalent AFE from a different vendor, coordinated sample testing, and validated compatibility within two weeks.

Thanks to this agile response, the project stayed on schedule, avoiding six-figure losses in delayed revenue and regulatory re-certification fees.

This case underscores how expert Hard-to-Find Electronic Components Sourcing can be a game-changer—not just operationally, but financially and strategically.

Building a Resilient Supply Chain for the Future

To thrive in an unpredictable environment, companies must move beyond reactive fixes and build resilient, adaptive supply chains. Key steps include:

- Conducting regular BOM health checks

- Developing dual-sourcing plans for critical components

- Establishing formal obsolescence management programs

- Investing in supply chain visibility tools

Organizations that treat Hard-to-Find Electronic Components Sourcing as a core competency—not an afterthought—are better positioned to innovate continuously and respond swiftly to change.

Conclusion: Turn Sourcing Challenges into Competitive Advantage

While the landscape of Hard-to-Find Electronic Components Sourcing remains challenging, it also presents opportunities for innovation and differentiation. By adopting proactive design practices, leveraging trusted partners, and utilizing advanced sourcing tools, companies can overcome scarcity and maintain production continuity.

Ultimately, success lies in preparation, collaboration, and agility. Whether you're designing a prototype or scaling up mass production, integrating smart sourcing strategies from day one will safeguard your timelines, budgets, and product quality.

If you're facing difficulties sourcing critical components for your next project, consider partnering with a reliable PCBA provider who specializes in comprehensive supply chain solutions. Visit our electronic component sourcing page to learn how we help clients navigate complex procurement challenges with confidence.