PCB Manufacturing

Advanced PCB manufacturing with cutting-edge technology and rigorous quality control

Manufacturing Capabilities

State-of-the-art equipment and proven processes for all PCB types

Layer Count

Board Thickness

Via Technology

Surface Finish

PCB Types We Manufacture

Comprehensive range of PCB technologies for every application

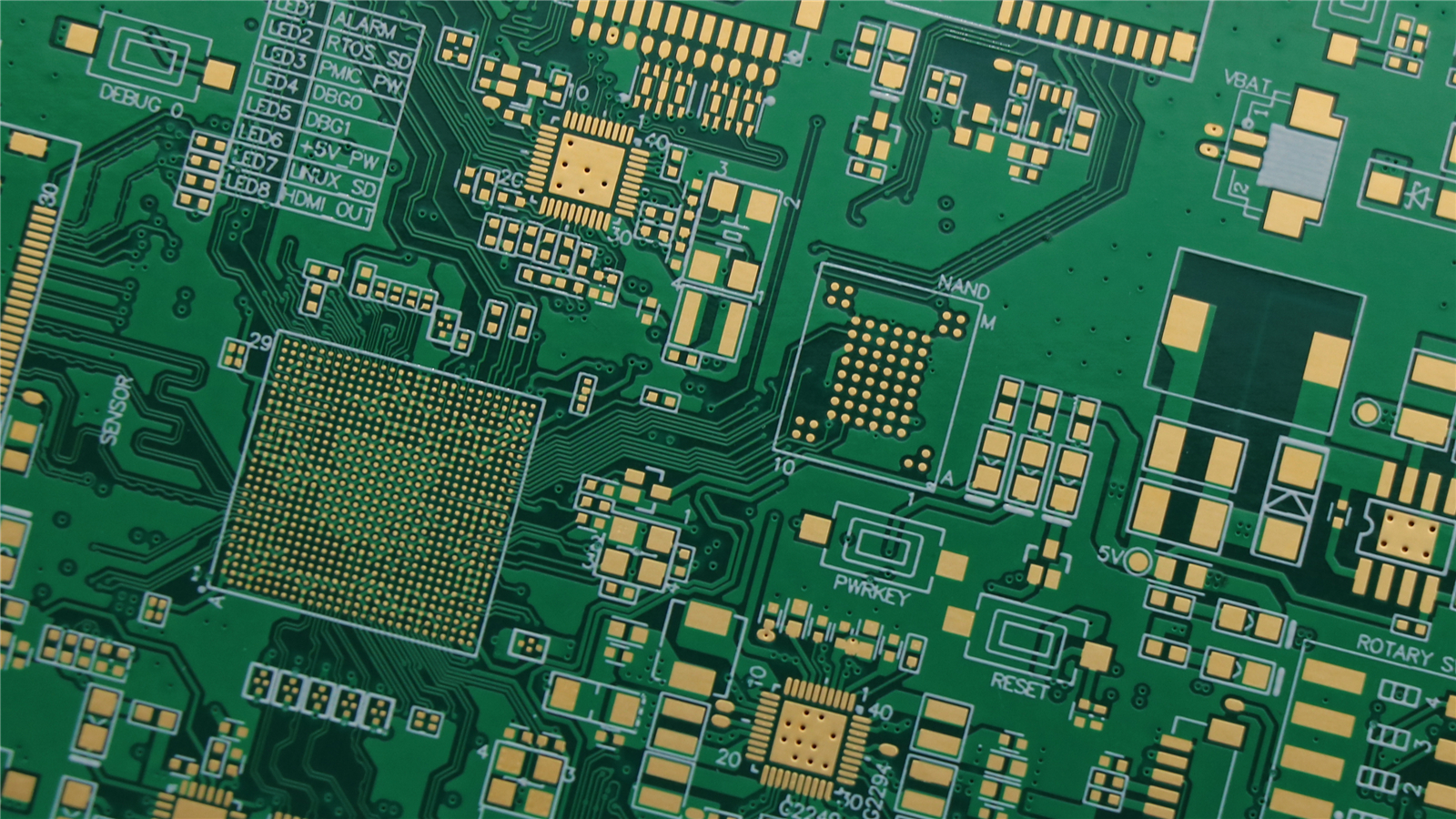

Rigid PCB

Traditional solid PCBs for standard applications

Key Features:

- Cost-effective

- High reliability

- Standard processes

- Quick turnaround

Applications:

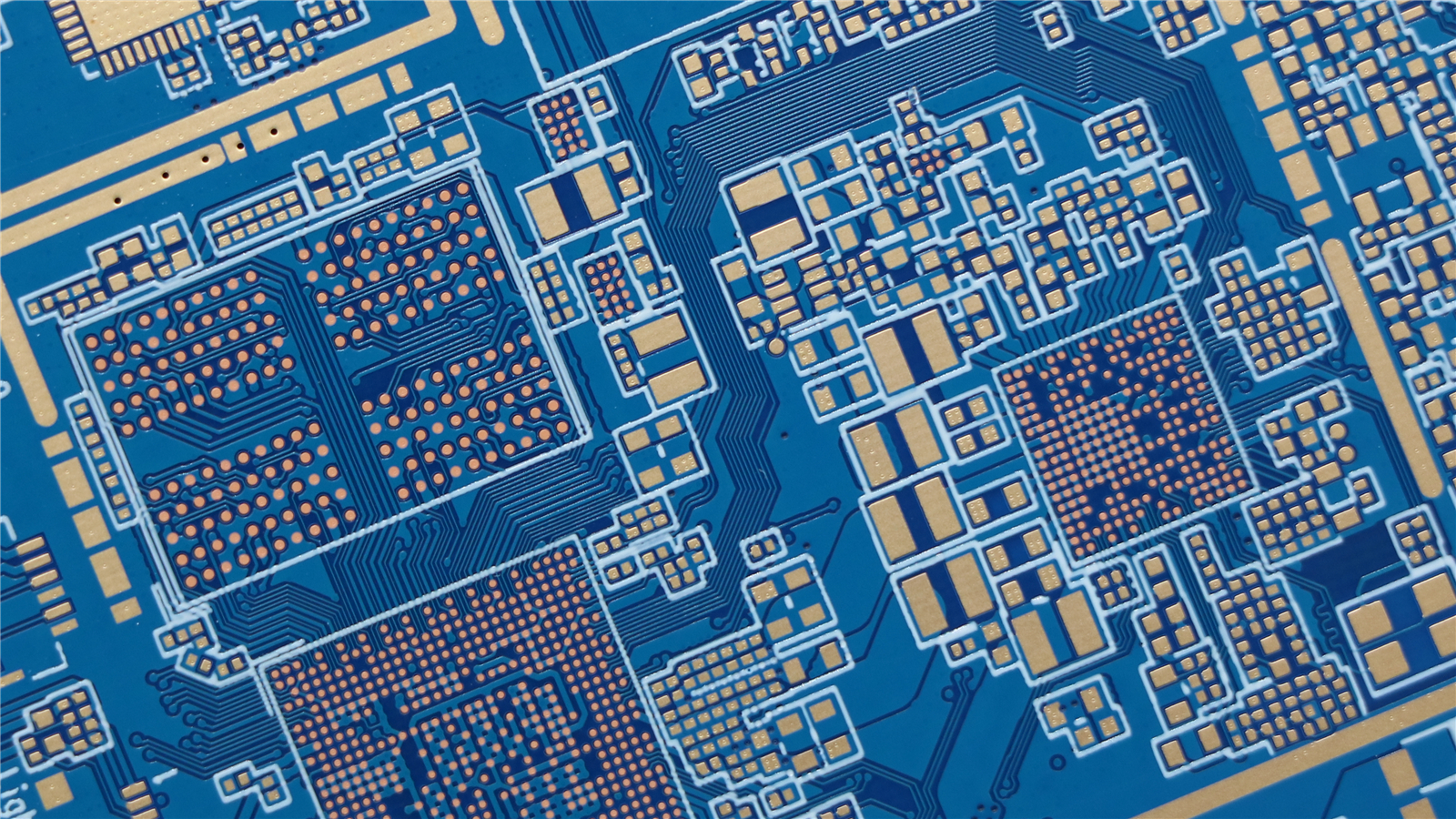

HDI PCB

High Density Interconnect for miniaturization

Key Features:

- Microvia technology

- Fine line width

- High component density

- Signal integrity

Applications:

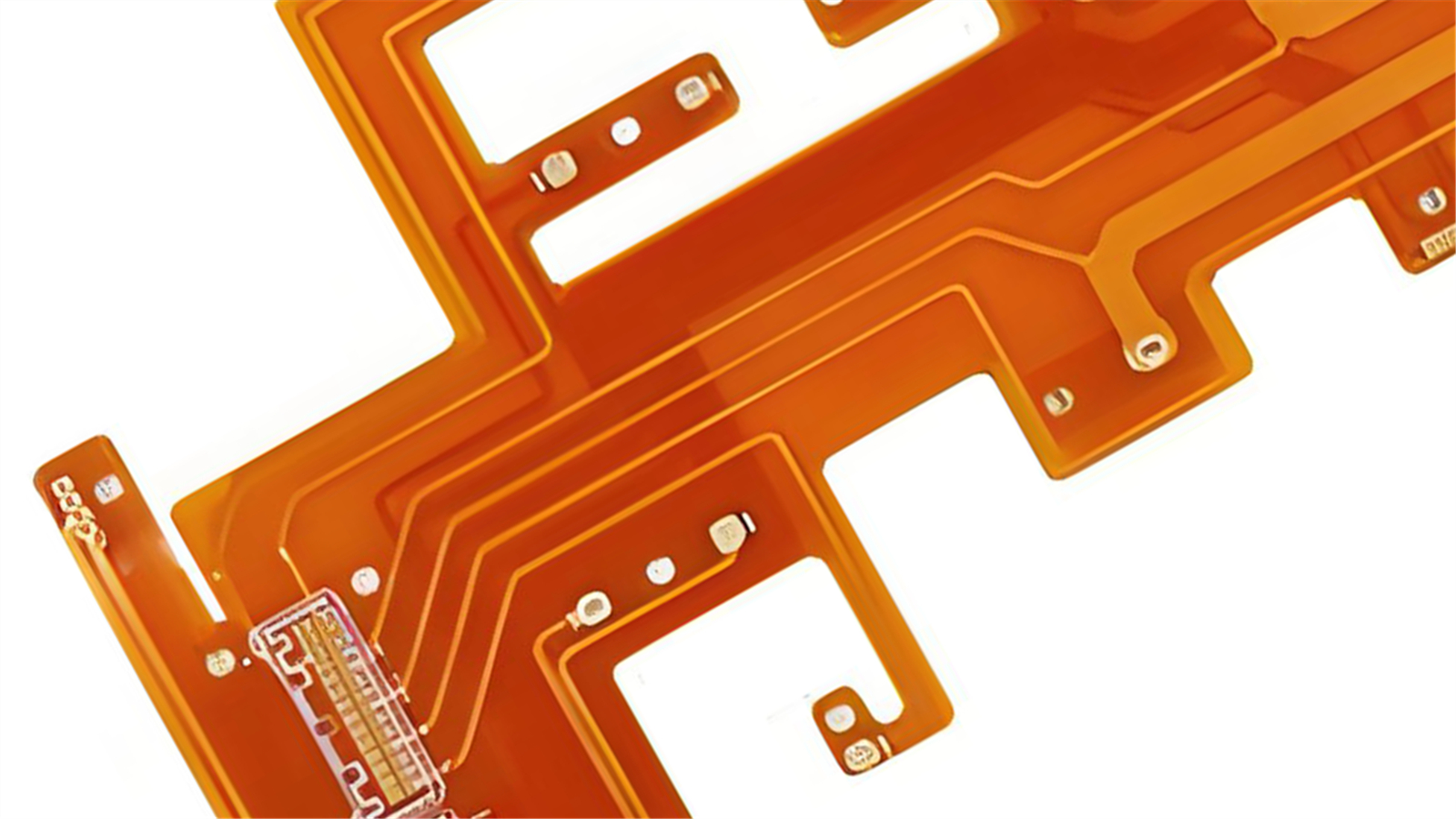

Flex PCB

Flexible circuits for space-constrained applications

Key Features:

- Bendable design

- Space saving

- Reduced weight

- Dynamic flexing

Applications:

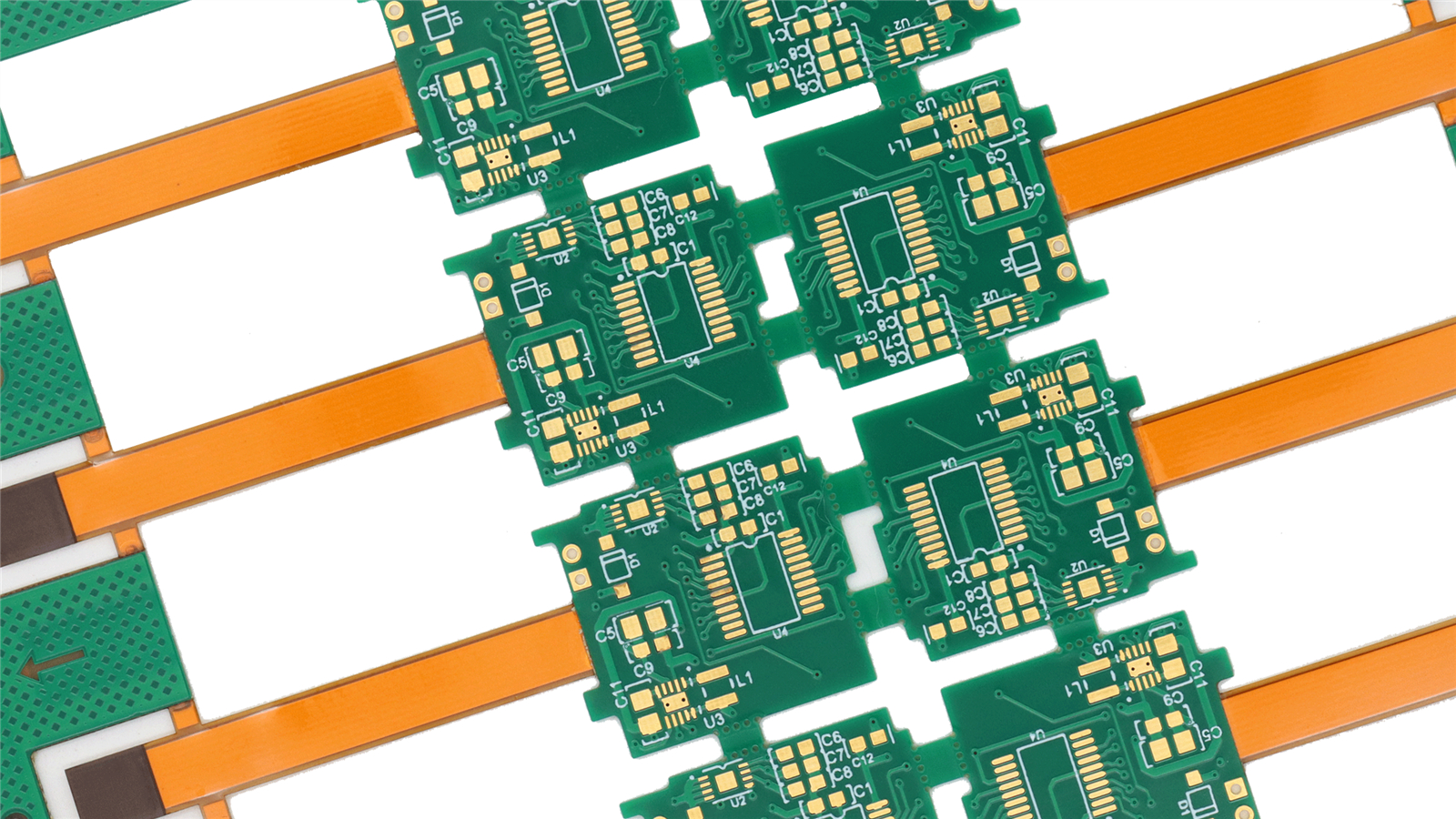

Rigid-Flex PCB

Combination of rigid and flexible sections

Key Features:

- 3D packaging

- Reduced connectors

- Improved reliability

- Complex designs

Applications:

Our Manufacturing Process

Systematic approach ensuring consistent quality and timely delivery

Design Review & DFM

1-2 DaysThorough analysis of your design files and manufacturing optimization recommendations.

Material Preparation

1-2 DaysSelection and preparation of substrate materials according to specifications.

Layer Stackup & Drilling

1-3 DaysPrecise layer alignment and high-accuracy drilling operations.

Plating & Etching

2-3 DaysCopper plating, pattern etching, and circuit formation.

Solder Mask & Silkscreen

1-2 DayApplication of solder mask and component labeling.

Surface Finish & Testing

1-2 DayFinal surface treatment and comprehensive electrical testing.

Quality Standards & Certifications

Compliance with international standards and industry best practices

IPC-6012

Qualification and Performance Specification for Rigid PCBs

IPC-6013

Qualification and Performance Specification for Flexible PCBs

IPC-6018

Microwave End Product Board Inspection and Test

ISO 9001:2015

Quality Management Systems

ISO 14001:2015

Environmental Management Systems

UL 94V-0

Flammability Rating for Plastic Materials

Ready to Start Your PCB Project?

Upload your design files and get a comprehensive quote with DFM analysis