Understanding Electronics Assembly: Process, Methods, and Best Practices

Winnie King

In today’s hyper-connected world, electronic devices are everywhere — from smartphones and smartwatches to medical equipment and autonomous vehicles. Behind every functioning gadget lies a complex network of circuits and components brought together through a precise and highly technical process known as electronics assembly. This critical phase transforms bare printed circuit boards (PCBs) into fully operational electronic systems that power innovation across industries.

But what exactly is electronics assembly, and why does it matter? Whether you're an engineer designing the next breakthrough device or a business leader sourcing manufacturing partners, understanding this process can significantly impact product quality, time-to-market, and cost-efficiency.

What Is Electronics Assembly?

Electronics assembly refers to the process of mounting and connecting electronic components onto a printed circuit board (PCB) to create a functional unit, often referred to as a PCBA (Printed Circuit Board Assembly). It goes beyond simple soldering; it involves a series of meticulously controlled steps including component placement, soldering, inspection, testing, and final validation.

This stage bridges the gap between PCB fabrication — where the physical board is manufactured — and the finished electronic product ready for integration into end-user devices. The accuracy and reliability of electronics assembly directly influence the performance, durability, and safety of the final product.

Modern electronics assembly leverages automation, robotics, and advanced materials to handle increasingly miniaturized components and high-density designs. As consumer demand pushes for smaller, faster, and more powerful electronics, manufacturers must adopt cutting-edge techniques to meet these challenges.

Key Stages in the Electronics Assembly Process

The electronics assembly workflow typically follows a standardized sequence designed to ensure consistency and quality. While variations exist depending on the type of components and board complexity, most processes include the following core stages:

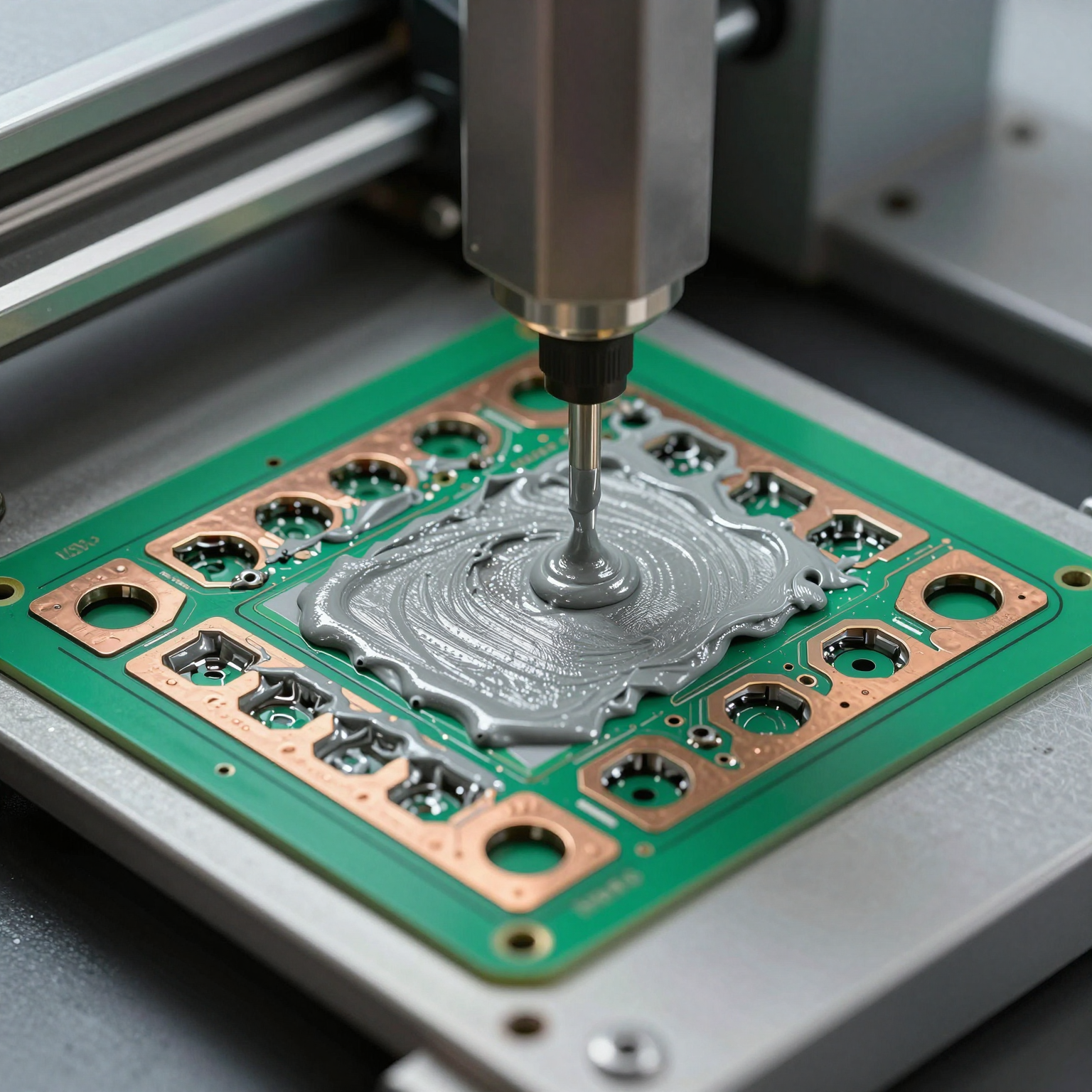

1. Solder Paste Application

The first step in surface mount technology (SMT) electronics assembly is applying solder paste to the PCB. A stencil is used to deposit a precise amount of paste — a mixture of tiny solder particles and flux — onto the pads where components will be placed. Accuracy here is crucial; too much or too little paste can lead to defects like bridging or insufficient joints.

Automated screen printers or jet dispensers ensure uniform application, especially important for fine-pitch components and high-volume production lines.

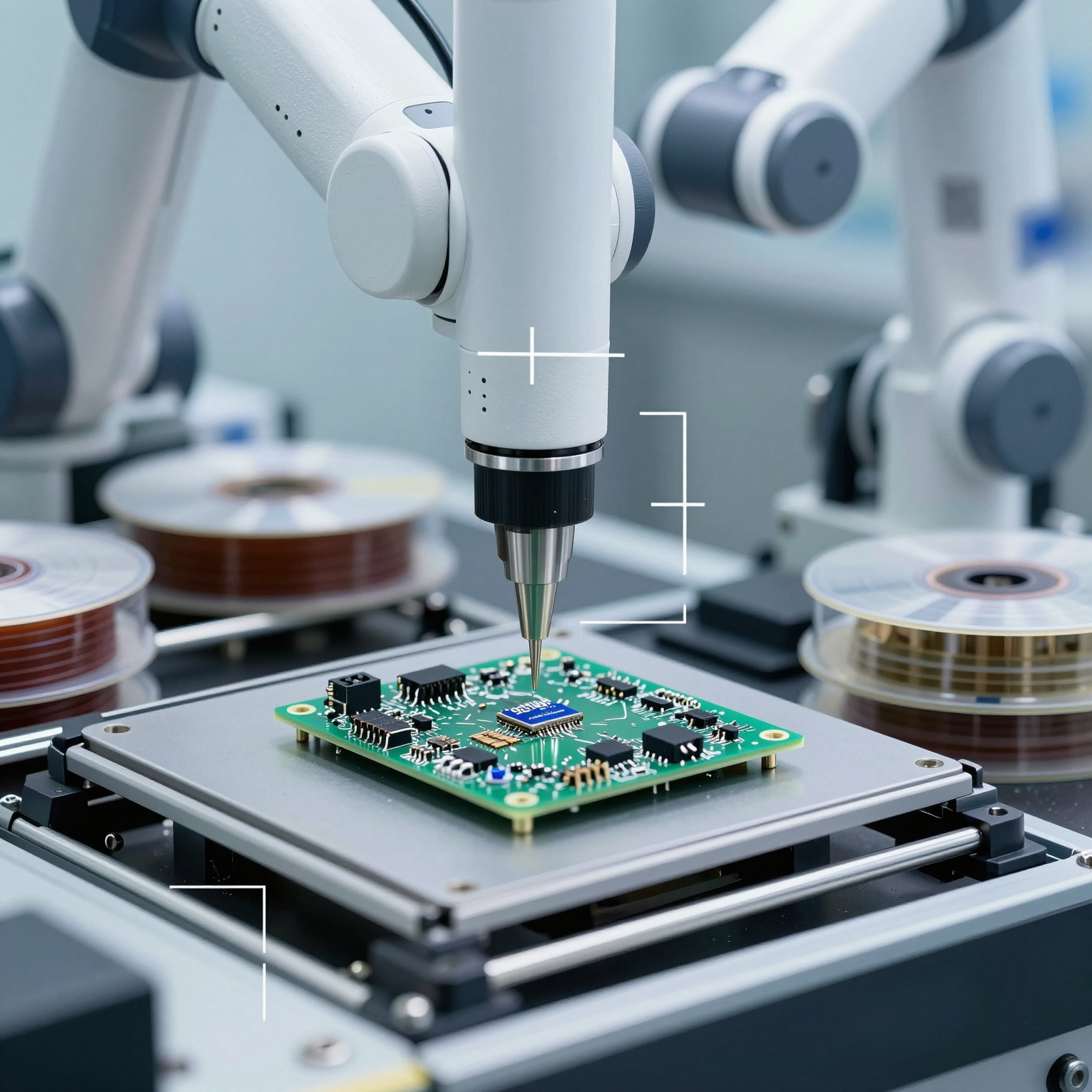

2. Component Placement

Once the solder paste is applied, automated pick-and-place machines position surface-mount devices (SMDs) onto the board with extreme precision. These machines use vision systems to align components correctly, often placing thousands per hour with micron-level accuracy.

For mixed-technology boards (those using both SMD and through-hole components), this stage focuses only on surface-mounted parts. Through-hole components are usually inserted later, either manually or via automated insertion machines.

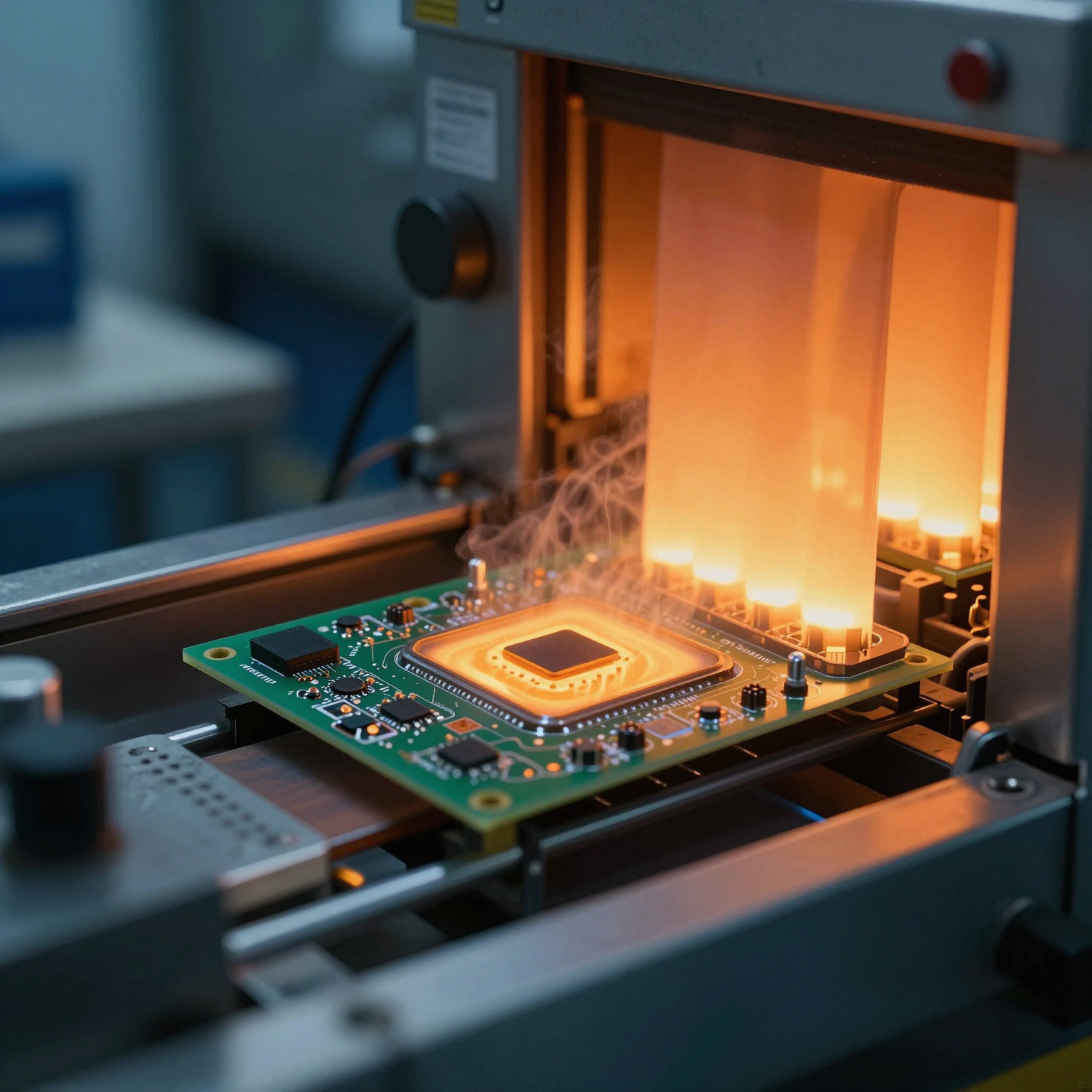

3. Reflow Soldering

After component placement, the board enters a reflow oven. Here, it is gradually heated according to a specific thermal profile, melting the solder paste and forming permanent electrical and mechanical connections. The cooling phase solidifies the joints, completing the SMT portion of the electronics assembly.

Temperature control is vital during reflow to avoid damaging sensitive components or creating cold solder joints.

4. Through-Hole Technology (THT) Assembly

Boards requiring through-hole components undergo additional processing. Components such as connectors, transformers, or large capacitors are inserted through drilled holes in the PCB. They are then soldered using wave soldering, selective soldering, or hand soldering methods.

Wave soldering passes the underside of the board over a molten solder wave, creating reliable joints. Selective soldering targets specific areas, ideal for boards with heat-sensitive zones or mixed technologies.

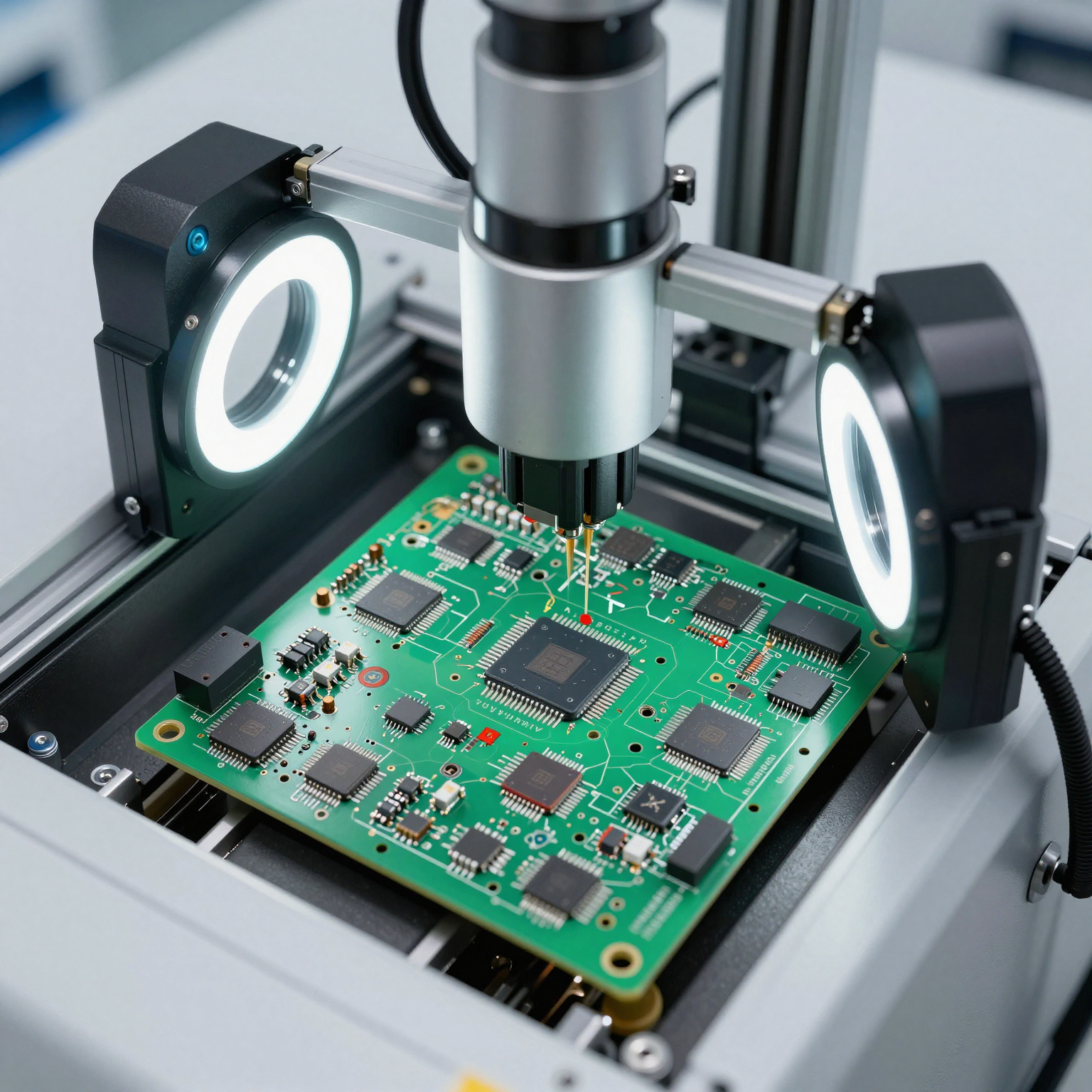

5. Inspection and Testing

Post-soldering, each assembled board undergoes rigorous inspection to detect defects. Automated Optical Inspection (AOI)

uses cameras and image processing software to identify missing components, misalignments, or solder flaws. X-ray inspection may also be employed for hidden joints, such as those under Ball Grid Arrays (BGAs).

Functional testing verifies that the board performs as intended under real operating conditions. In-circuit testing (ICT) checks individual components and connections for correctness.

6. Final Cleaning and Conformal Coating

Depending on the application environment, boards may be cleaned to remove flux residues or coated with a protective layer called conformal coating. This thin polymer film shields against moisture, dust, chemicals, and temperature extremes — essential for automotive, industrial, and outdoor electronics.

Common Electronics Assembly Techniques

Different products require different approaches. The two primary electronics assembly methods are Surface Mount Technology (SMT) and Through-Hole Technology (THT), each with distinct advantages.

Surface Mount Technology (SMT)

SMT dominates modern electronics assembly due to its ability to support compact, lightweight designs. Components are mounted directly onto the surface of the PCB, allowing for higher component density and double-sided assembly. SMT enables faster production speeds and better performance at high frequencies.

However, SMT components are generally less mechanically robust than their through-hole counterparts, making them less suitable for environments with high vibration or stress.

Learn more about how SMT compares to traditional methods in our detailed guide on SMT vs through-hole assembly.

Through-Hole Technology (THT)

THT involves inserting component leads through holes in the PCB and soldering them on the opposite side. Though largely supplanted by SMT in consumer electronics, THT remains relevant for applications requiring superior strength and reliability — such as aerospace, military, and heavy industrial equipment.

While slower and more labor-intensive, THT offers excellent durability and easier prototyping, which is why it's still widely used in certain sectors.

Advanced Trends Shaping Modern Electronics Assembly

As technology evolves, so do the demands placed on electronics assembly. Several emerging trends are redefining how electronics are built:

Miniaturization and HDI Boards

High-Density Interconnect (HDI) PCBs allow for smaller vias, tighter trace spacing, and greater functionality in reduced footprints. These boards are common in wearables, smartphones, and medical implants. Their complexity requires advanced electronics assembly techniques, including micro-via filling, sequential lamination, and laser drilling.

To stay competitive, manufacturers invest heavily in HDI-compatible equipment and cleanroom environments.

Flexible and Rigid-Flex Circuits

Flexible PCBs (FPCs) and rigid-flex hybrids enable innovative form factors by allowing circuits to bend and conform to 3D spaces. Used in foldable phones, medical sensors, and drones, their assembly demands specialized handling due to material fragility.

Static control, low-force placement tools, and tailored reflow profiles are essential for successful electronics assembly of flexible substrates.

Automation and Industry 4.0 Integration

Smart factories leverage IoT-enabled machines, AI-driven analytics, and real-time monitoring to optimize electronics assembly lines. Predictive maintenance reduces downtime, while machine learning algorithms improve yield rates by identifying subtle defect patterns.

Digital twins simulate the entire assembly process before physical production begins, reducing errors and accelerating ramp-up times.

Quality Assurance in Electronics Assembly

No discussion of electronics assembly would be complete without emphasizing quality. Even minor flaws — such as a single cold solder joint — can cause catastrophic failures in critical systems like medical devices or avionics.

A robust quality management system includes multiple checkpoints throughout the process:

- Pre-production design reviews (DFM/DFA)

- Incoming component inspection

- In-process AOI and AXI (Automated X-ray Inspection)

- Final functional and environmental testing

- Traceability via barcode/RFID tagging

Many leading manufacturers follow IPC-A-610 standards for acceptability of electronic assemblies, ensuring global consistency in quality expectations.

One effective approach is implementing a 6-step quality control process, which ensures comprehensive oversight from raw materials to shipping.

Choosing the Right Partner for Your Electronics Assembly Needs

Outsourcing electronics assembly to a qualified contract manufacturer (CM) can offer significant benefits, including access to advanced technology, scalable capacity, and supply chain expertise. When evaluating potential partners, consider the following:

- Technical capabilities (SMT, THT, HDI, FPC)

- Range of services offered (e.g., component sourcing, testing, box build)

- Certifications (ISO 9001, IPC, AS9100 for aerospace)

- Supply chain resilience and component availability

- Turnaround time and scalability

A full-service provider like a professional PCB assembly manufacturer can manage everything from prototype development to mass production, ensuring seamless transition from design to delivery.

Additionally, turnkey solutions streamline the process by handling component procurement, inventory management, and logistics — freeing up internal resources for innovation and market strategy.

Conclusion

Electronics assembly is far more than just attaching parts to a board — it's a sophisticated engineering discipline that combines precision, materials science, and digital intelligence. From the initial paste application to final testing, every step plays a role in determining the success of the end product.

As devices become smarter, smaller, and more interconnected, the importance of reliable, high-quality electronics assembly continues to grow. By embracing advanced technologies, adhering to strict quality protocols, and partnering with experienced manufacturers, companies can bring innovative products to market faster and more efficiently.

Whether you're developing a new IoT sensor or upgrading legacy systems, investing in a deep understanding of electronics assembly processes and best practices will pay dividends in performance, reliability, and customer satisfaction.

For further reading, explore our complete guide to PCB assembly to dive deeper into each stage of the journey from concept to completion.