Electronics Manufacturer Service: Your Complete Guide to Reliable Electronics Manufacturing

Winnie King

What Is Electronics Manufacturer Service?

In today’s fast-paced technology landscape, bringing a new electronic product to market requires more than just a great idea—it demands precision, scalability, and speed. This is where Electronics Manufacturer Service comes into play. An Electronics Manufacturer Service provides comprehensive support for companies looking to design, prototype, produce, and test electronic devices at scale.

These services typically cover the full spectrum of electronics manufacturing, from printed circuit board (PCB) fabrication and component sourcing to final assembly, testing, and logistics. Whether you're a startup developing a smart home device or an established company scaling up production, partnering with a reliable service provider ensures consistency, compliance, and cost-efficiency.

At its core, Electronics Manufacturer Service bridges the gap between concept and commercialization by offering technical expertise, advanced equipment, and streamlined processes that most in-house teams cannot match.

Key Components of Electronics Manufacturing

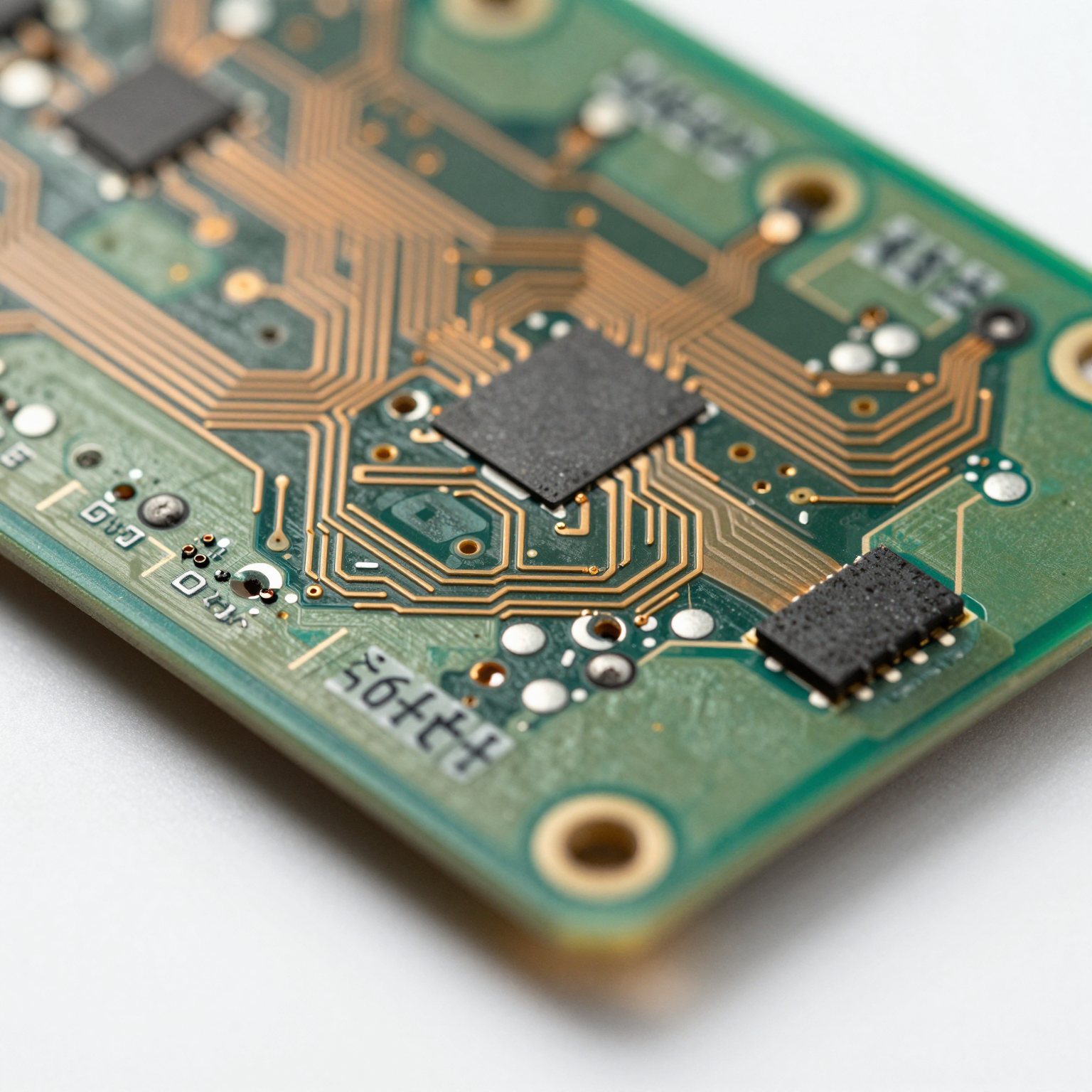

PCB Fabrication and Assembly

The foundation of any electronic device lies in its printed circuit board. **PCB fabrication

** involves creating bare boards using specialized materials like FR-4, Rogers, or flexible substrates. Once fabricated, these boards move into the assembly phase—commonly known as PCB assembly services—where surface mount technology (SMT), through-hole, or mixed-technology methods are used to place components.

Modern electronics manufacturing facilities use automated pick-and-place machines, reflow ovens, and AOI (Automated Optical Inspection) systems to ensure high accuracy and throughput. For complex designs such as HDI (High-Density Interconnect) or RF circuits, manufacturers must adhere to strict design rules and material specifications to maintain signal integrity and performance.

To learn more about how PCBs go from raw materials to functional boards, check out this introduction to PCB manufacturing.

Component Sourcing

and Supply Chain Management

One of the biggest challenges in modern electronics production is securing reliable access to electronic components. Global supply chain disruptions, long lead times, and counterfeit parts have made electronic component sourcing a critical function within Electronics Manufacturer Service.

Reputable providers offer full parts procurement solutions, leveraging global supplier networks to source genuine components at competitive prices. They also provide alternatives when certain parts are unavailable, ensuring production timelines aren’t compromised. This level of supply chain resilience is essential for maintaining continuity, especially during periods of semiconductor shortages.

For insight into best practices for managing component availability, see our detailed electronic components sourcing guide.

Prototyping and Low-Volume

Production

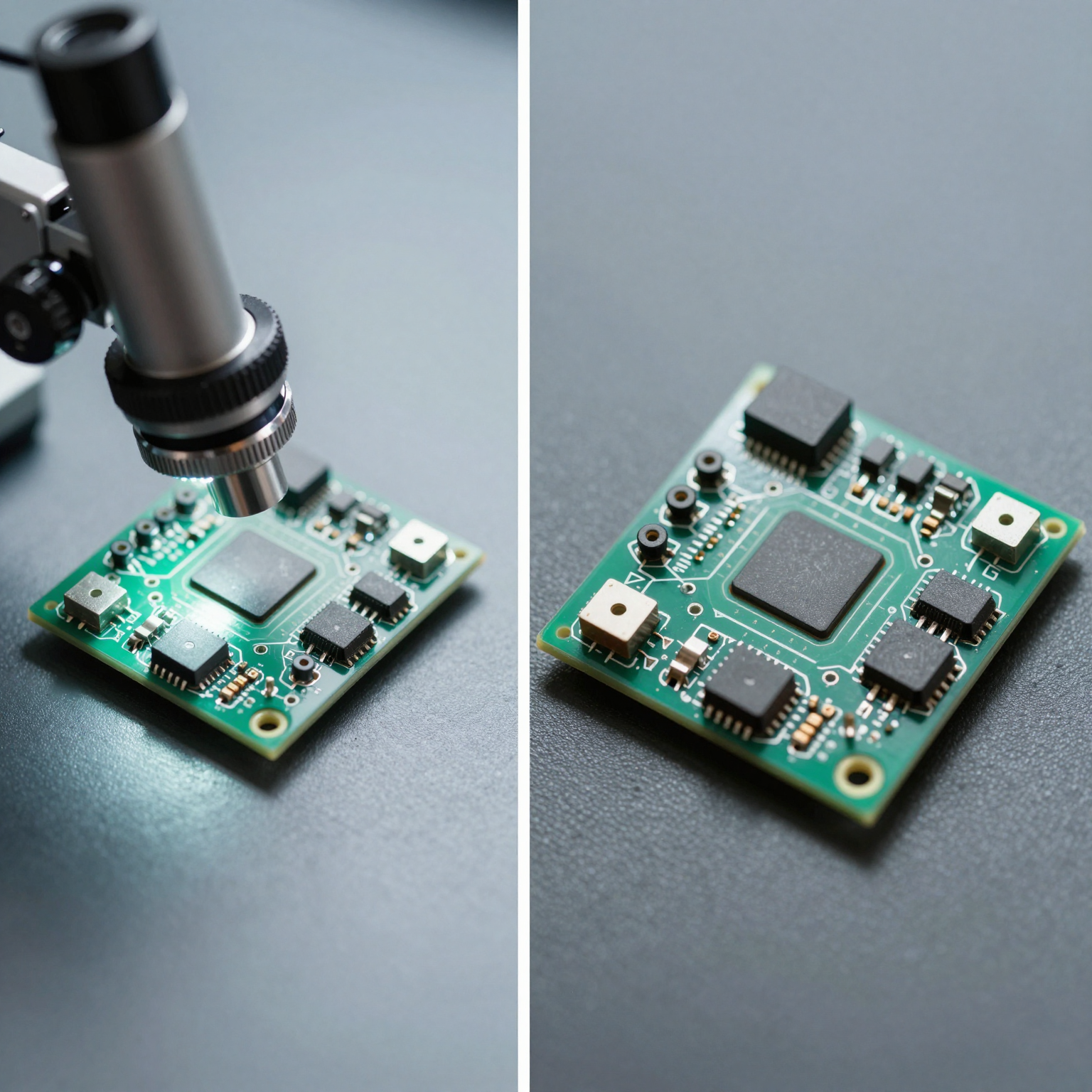

Before committing to mass production, most companies require functional prototypes to validate design, perform testing, and secure certifications. A strong Electronics Manufacturer Service supports rapid prototyping with quick-turn PCB fabrication and assembly, often delivering working units in under two weeks.

Prototyping isn't just about speed—it's about fidelity. High-quality prototypes should mirror final production units as closely as possible, allowing engineers to identify thermal, electrical, or mechanical issues early. Many services now offer turnkey PCB assembly for prototypes, handling everything from bill-of-materials (BOM) validation to final packaging.

For a step-by-step walkthrough, explore our prototype PCB assembly guide.

Full Turnkey and Consignment Models

Businesses can choose between different engagement models depending on their needs:

- Turnkey: The manufacturer handles all aspects—from component sourcing to final assembly.

- Consignment: The client supplies all components; the manufacturer focuses only on assembly.

While consignment gives more control over part selection, it shifts supply chain risk back to the customer. In contrast, turnkey solutions reduce overhead and simplify logistics but require trust in the manufacturer’s sourcing capabilities. Most modern electronics manufacturing partners recommend turnkey for startups and mid-sized businesses due to its efficiency and scalability.

Why Choose a Professional Electronics Manufacturer?

Quality Assurance

and Testing

Quality is non-negotiable in electronics. Defective products can lead to recalls, reputational damage, and safety hazards. That’s why every reputable Electronics Manufacturer Service implements rigorous quality assurance protocols throughout the production cycle.

Standard procedures include:

- Automated Optical Inspection (AOI)

- X-ray inspection for BGA and hidden solder joints

- In-circuit testing (ICT)

- Functional testing under real-world conditions

Many manufacturers follow ISO 9001 standards and employ a multi-stage quality control process. For example, some companies utilize a documented 6-step quality control process to ensure zero-defect delivery across batches.

Scalability and Flexibility

From one-off prototypes to millions of units, professional electronics manufacturing services are built to scale. Advanced factories feature modular production lines that can be reconfigured quickly based on project requirements.

This flexibility allows companies to start small, gather market feedback, and then ramp up production seamlessly—without changing vendors or redesigning processes. It also supports regional customization, enabling localized versions of products for different markets.

Faster Time-to-Market

Speed is a competitive advantage. With integrated Electronics Manufacturer Service, companies avoid the delays associated with coordinating multiple vendors. Instead, they work with a single point of contact who manages design review, fabrication, assembly, testing, and shipping.

By streamlining workflows and reducing handoffs, manufacturers help clients cut development cycles by 30–50%. This acceleration is crucial in industries like consumer electronics, IoT, and medical devices, where being first to market can define success.

Industries Served by Electronics Manufacturer Services

Electronics Manufacturer Service plays a vital role across numerous sectors:

- Consumer Electronics: Smartphones, wearables, audio devices

- Medical Devices: Patient monitors, diagnostic tools, implantables

- Industrial Automation: Control systems, sensors, HMIs

- Automotive: ADAS, infotainment, EV power systems

- Telecommunications: Routers, base stations, fiber optics

- Aerospace & Defense: Avionics, radar systems, secure comms

Each industry has unique regulatory and performance demands. For instance, medical-grade electronics must comply with FDA regulations, while automotive applications need to meet AEC-Q100 component stress testing standards. A capable electronics manufacturing partner understands these nuances and tailors processes accordingly.

Explore which markets are supported by visiting the industries served by PCB manufacturer page.

How to Select the Right Electronics Manufacturer Service

Choosing the right partner involves evaluating several key factors:

Technical Capabilities

Ensure the manufacturer supports your required technologies:

- HDI and rigid-flex PCBs

- Micro BGAs and fine-pitch components

- RF and high-speed digital design

- Specialized finishes like ENIG or immersion silver

Review their PCB manufacturing capabilities to confirm compatibility with your design complexity.

Certifications and Compliance

Look for ISO 9001, IATF 16949 (automotive), or ISO 13485 (medical) certifications. These demonstrate a commitment to quality systems and traceability.

Customer Support and Communication

Responsive communication, engineering support, and transparent reporting are hallmarks of a good partner. You should receive regular updates on production status, yield rates, and potential issues.

Cost vs. Value

While cost matters, focus on total value. A slightly higher price may reflect better quality, faster turnaround, or superior after-sales service. Request a quote early to assess affordability and clarity.

You can get a PCB quote directly through trusted providers to compare pricing and lead times.

The Future of Electronics Manufacturing

Advancements in automation, AI-driven inspection, and sustainable manufacturing are shaping the next generation of Electronics Manufacturer Service. Trends include:

- Increased adoption of Industry 4.0 principles for real-time monitoring

- Use of machine learning to predict solder joint failures

- Growth in eco-friendly materials and lead-free assembly

- Expansion of local manufacturing hubs to reduce dependency on offshore supply chains

Additionally, demand for miniaturized, connected devices continues to drive innovation in electronics manufacturing, particularly in wearable tech, edge computing, and smart infrastructure.

Staying ahead means partnering with a forward-thinking provider who invests in R&D and embraces emerging technologies like flexible PCBs and embedded passives.

For deeper insights into future trends, read about HDI PCB technology trends.

Conclusion

An effective Electronics Manufacturer Service is more than just a contract assembler—it's a strategic partner in innovation. By combining technical excellence, scalable operations, and end-to-end accountability, these services empower businesses to bring sophisticated electronic products to life efficiently and reliably.

Whether you're launching your first prototype or preparing for global distribution, choosing the right electronics manufacturing partner can make all the difference. Focus on quality, responsiveness, and proven experience to ensure your product meets both market expectations and regulatory standards.

Ready to take the next step? Learn more about available offerings through PCB services or reach out to discuss your specific needs with an expert team.