Electronic Components Sourcing for Prototyping: A Strategic Guide to Supply

Rosannie Rolling

Bringing an electronic idea to life begins long before solder touches board—it starts with Electronic Components Sourcing for Prototyping. Whether you're a solo inventor, a startup founder, or part of an R&D team at an established company, securing the right parts quickly and reliably is foundational to turning concepts into working prototypes. In today’s dynamic electronics landscape, where component shortages and lead time volatility are common, understanding the nuances of electronics components supply can make the difference between rapid innovation and project stagnation.

This guide dives deep into the world of component procurement specifically tailored for prototyping, offering strategic insights to help engineers and product developers navigate sourcing challenges efficiently.

Why Prototyping Demands a Different Sourcing Approach

Prototyping differs significantly from full-scale production in volume, cost sensitivity, and timeline pressures. While mass manufacturing prioritizes bulk pricing and long-term supplier contracts, prototyping focuses on speed, flexibility, and access to small quantities—even single units—of diverse components.

Key characteristics of prototyping-focused Electronic Components Sourcing for Prototyping include:

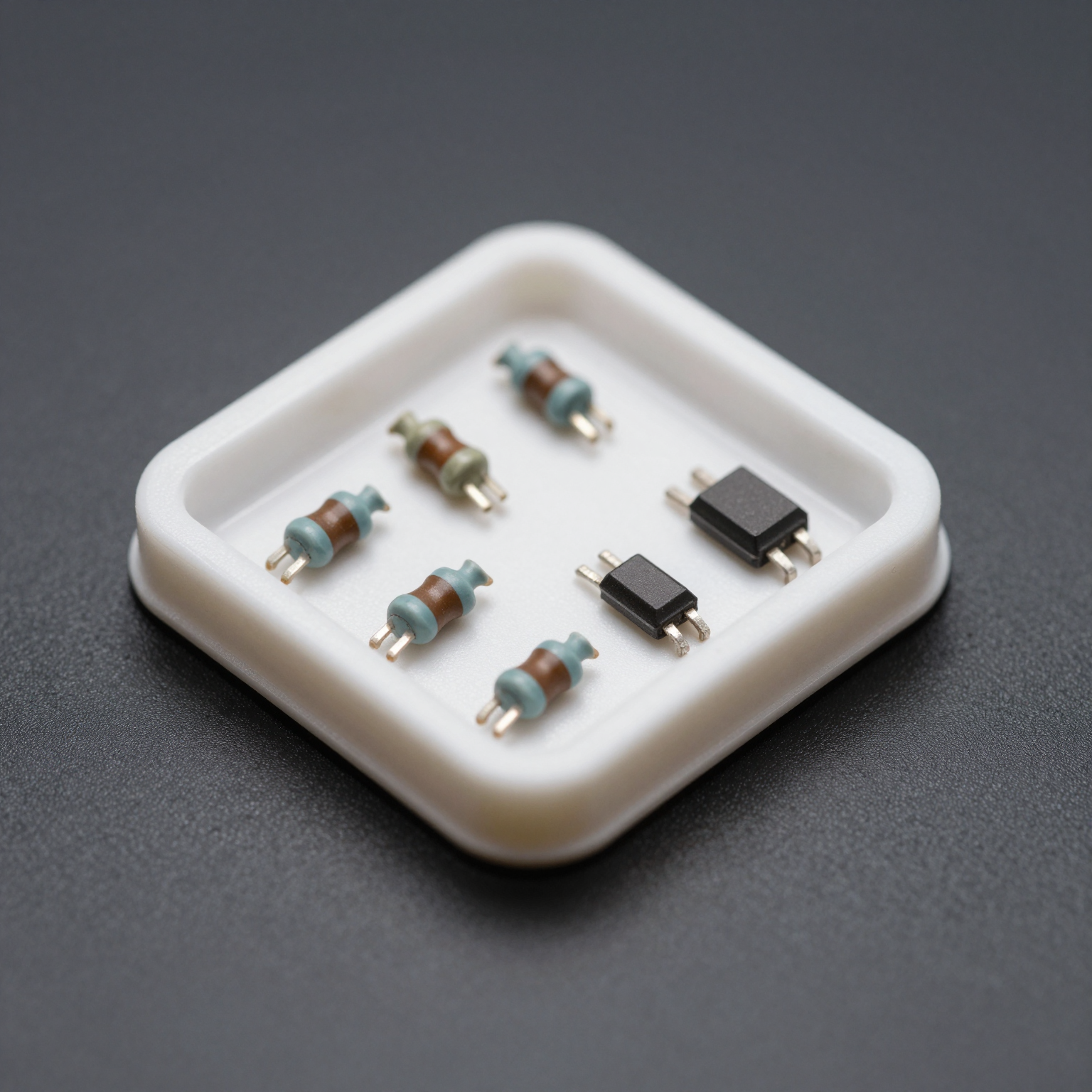

- **Low-volume requirements

**: Engineers often need just a few pieces of each component.

- Broad component variety: Projects may require everything from common resistors to specialized sensors or obsolete ICs.

- Speed-to-test: Rapid iteration cycles demand fast turnaround on parts delivery.

- Risk tolerance: Design changes are frequent; overstocking must be avoided.

These factors necessitate a sourcing strategy that balances availability, cost, and reliability without locking into large inventories.

Common Channels for Electronic Components Supply in Prototyping

Engineers have several options when it comes to acquiring components for early-stage development. Each channel has its strengths and limitations depending on your project needs.

1. Authorized Distributors

(e.g., Digi-Key, Mouser, RS Components)

Authorized distributors are often the go-to source for Electronic Components Sourcing for Prototyping due to their vast inventories, real-time stock visibility, and guaranteed authenticity. Platforms like Digi-Key and Mouser Electronics offer millions of components with detailed specifications, datasheets, and parametric search tools that simplify part selection.

Pros:

- Guaranteed genuine components

- Excellent technical documentation

- Fast shipping (often same-day)

- Support for very low order quantities

Cons:

- Higher per-unit prices compared to bulk purchases

- Limited availability of end-of-life (EOL) or obsolete parts

These distributors are ideal for standard components such as passive elements (resistors, capacitors), microcontrollers, connectors, and development boards.

2. Independent Distributors and Brokers

When a required component is discontinued or in short supply, independent distributors step in. These suppliers source parts from secondary markets, excess inventory, or liquidation sales.

While they can rescue stalled projects by locating rare components, caution is advised. Risks include counterfeit parts, incorrect grading (e.g., commercial vs. industrial temperature range), and inflated pricing during scarcity events.

To mitigate risk:

- Verify distributor certifications (e.g., AS6496 standard)

- Request full traceability documentation

- Use third-party testing when feasible

For mission-critical applications, especially in aerospace, medical, or defense sectors, extra diligence is non-negotiable.

3. Direct from Manufacturers

(OEMs)

Some semiconductor manufacturers, like Texas Instruments, Analog Devices, or STMicroelectronics, offer sample programs allowing engineers to request free or low-cost evaluation units. This is particularly valuable for testing new ICs before committing to larger orders.

However, these samples are typically limited in quantity and intended solely for evaluation—not for building multiple prototypes or pre-production units.

4. Online Marketplaces (e.g., eBay, Amazon)

Platforms like eBay or Amazon can be useful for sourcing hard-to-find or legacy components. However, buyer beware: there's little oversight regarding authenticity or condition. These channels should be used cautiously and only when no other option exists.

Always check seller ratings, ask for lot numbers or date codes, and factor in potential rework if substandard parts are received.

Best Practices for Effective Electronic Components Sourcing for Prototyping

To streamline the electronics components supply process and avoid delays, follow these best practices:

Start with a Well-Defined BOM (Bill of Materials)

A comprehensive and accurate Bill of Materials is your roadmap for sourcing success. Ensure each entry includes:

- Manufacturer Part Number (MPN)

- Description

- Quantity

- Package type

- Tolerance/rating (e.g., voltage, temperature)

- Preferred supplier(s)

Using standardized formats helps prevent confusion and speeds up procurement, especially when collaborating with contract manufacturers.

Leverage Cross-Reference Tools

If a preferred component is unavailable, use cross-reference tools provided by distributors or third-party platforms to identify functional equivalents. Be cautious: not all “pin-compatible” parts behave identically under load or across temperature ranges. Always validate substitutions through simulation or bench testing.

Design with Availability in Mind

Smart design choices can reduce dependency on scarce components. Consider:

- Using common footprints that allow multiple vendor options

- Choosing components with multiple sourcing paths

- Avoiding ultra-miniaturized packages unless absolutely necessary (they’re harder to hand-solder and more prone to obsolescence)

Designing for supply chain resilience increases the likelihood that your prototype can evolve smoothly into production.

Monitor Lifecycle Status

Check the lifecycle status of critical components early. Many manufacturers publish Product Change Notices (PCNs) indicating impending obsolescence. Tools like SiliconExpert or Octopart integrate lifecycle data directly into part searches, helping you avoid components nearing discontinuation.

The Role of Contract Manufacturers in Component Sourcing

For startups and smaller teams, managing component procurement alongside design and testing can be overwhelming. This is where partnering with a full-service electronics manufacturer becomes invaluable.

Many modern PCB assembly providers offer integrated electronic component sourcing as part of their service portfolio. By leveraging economies of scale and established supplier relationships, these partners can often secure components faster and at better rates than individual buyers.

For example, a turnkey PCB assembly services provider handles everything from bare board fabrication to component procurement and final assembly—freeing engineers to focus on innovation rather than logistics.

Benefits include:

- Reduced administrative burden

- Access to bulk pricing and long-term agreements

- Proactive risk mitigation (e.g., identifying alternates early)

- Quality assurance throughout the supply chain

When selecting a partner, inquire about their sourcing capabilities, quality controls, and ability to support both prototyping and scaling into volume production.

Managing Risk in the Electronics Components Supply Chain

The global semiconductor shortage of recent years highlighted vulnerabilities in the electronics components supply ecosystem. Geopolitical tensions, natural disasters, and sudden shifts in demand can disrupt availability overnight.

Strategies to build resilience:

- Dual-source critical components whenever possible

- Maintain buffer stock of key items expected to have long lead times

- Engage early with suppliers to secure allocation

- Use modular design principles to facilitate easier component swaps

Additionally, consider nearshoring or regional sourcing options to reduce dependency on distant logistics networks.

From Prototype to Production: Ensuring a Smooth Transition

One of the hidden pitfalls in Electronic Components Sourcing for Prototyping is assuming that parts available in small quantities will remain accessible at scale. A component easily bought one-at-a-time online might have a 52-week lead time when ordered in thousands.

To bridge this gap:

- Conduct a formal Design for Manufacturability (DFM) and Design for Supply Chain (DFSC) review before transitioning

- Align with your CM on final component selections

- Lock in preferred vendors and negotiate initial purchase agreements

Doing so ensures continuity and prevents costly redesigns late in the development cycle.

Conclusion: Building Smarter with Strategic Sourcing

Effective Electronic Components Sourcing for Prototyping isn’t just about finding parts—it’s about building a resilient foundation for innovation. By choosing the right channels, designing with supply in mind, and leveraging expert partners, engineers can accelerate development, reduce risk, and bring products to market faster.

Whether you're sourcing a handful of resistors or navigating complex IC availability, remember that every decision made during the prototype phase echoes through the entire product lifecycle. Make them wisely.

For teams looking to offload the complexities of parts procurement, exploring professional solutions like electronic component sourcing can provide significant advantages in speed, reliability, and scalability.