Cost-Effective Electronic Components Sourcing: Smart Strategies for Success

Rosannie Rolling

In today’s fast-paced electronics industry, balancing performance, reliability, and budget is more critical than ever. One of the most impactful ways to maintain this balance is through Cost-Effective Electronic Components Sourcing. Whether you're a startup developing a prototype or an established company scaling production, the way you source electronic parts directly affects your product's time-to-market, overall cost, and long-term success.

Electronic components—resistors, capacitors, ICs, connectors, and more—can account for up to 70% of the total bill of materials (BOM) in some products. With global supply chain volatility, component shortages, and fluctuating prices, inefficient sourcing can lead to delays, inflated costs, and compromised quality. On the other hand, a strategic approach to Cost-Effective Electronic Components Sourcing ensures access to high-quality parts at competitive prices, reduces risk, and improves project scalability.

This guide explores actionable strategies, tools, and partnerships that empower businesses to achieve optimal results in their component procurement process.

Understanding the Challenges in Component Sourcing

Before diving into solutions, it's important to recognize the common hurdles in Cost-Effective Electronic Components Sourcing:

1. Supply Chain Volatility

Global disruptions—ranging from geopolitical tensions to natural disasters—can severely impact the availability of key components. The semiconductor shortage of recent years highlighted just how fragile the supply chain can be.

2. Obsolescence and Lifecycle Management

Many electronic components have limited production lifecycles. Relying on obsolete or end-of-life (EOL) parts can jeopardize long-term production unless managed proactively.

3. Counterfeit Components

The risk of counterfeit or substandard parts entering the supply chain is real, especially when sourcing from less-regulated distributors. These components can fail prematurely, leading to costly recalls or reputational damage.

4. Price Fluctuations

Component pricing isn't static. Demand surges, tariffs, and distributor markups can all cause sudden price increases, making budget forecasting difficult.

5. Lead Times and Minimum Order Quantities (MOQs)

Long lead times and high MOQs can be problematic for startups or low-volume producers, tying up capital and delaying development cycles.

Addressing these challenges requires a proactive, well-informed strategy focused on Cost-Effective Electronic Components Sourcing without compromising integrity.

Strategies for Cost-Effective Electronic Components Sourcing

Achieving cost efficiency in component procurement doesn’t mean choosing the cheapest option—it means maximizing value across cost, quality, availability, and support. Here are five proven strategies:

1. Design for Procurement Early

Integrate sourcing considerations into the design phase. Use common, widely available components instead of specialized or proprietary ones whenever possible. This not only reduces cost but also improves supply resilience.

Tools like BOM management software can help identify alternative parts, check lifecycle status, and compare distributor pricing in real time. For example, platforms such as Octopart or Ultra Librarian allow engineers to cross-reference components across multiple suppliers instantly.

Pro Tip: Always include second-source options in your BOM to mitigate single-supplier dependency.

2. Leverage Authorized Distributors

While independent brokers may offer lower prices, they carry higher risks of counterfeit or excess inventory. Prioritize authorized distributors like Digi-Key, Mouser, or Arrow Electronics, which guarantee authenticity and traceability.

These partners often provide volume discounts, technical support, and detailed datasheets—adding value beyond just price.

3. Consolidate Suppliers and Orders

Working with fewer, trusted suppliers simplifies logistics, improves negotiation power, and enhances relationship management. Bulk purchasing agreements can unlock better pricing and priority fulfillment during shortages.

Additionally, consolidating orders reduces administrative overhead and shipping costs, contributing to Cost-Effective Electronic Components Sourcing.

4. Partner with Full-Service Manufacturers

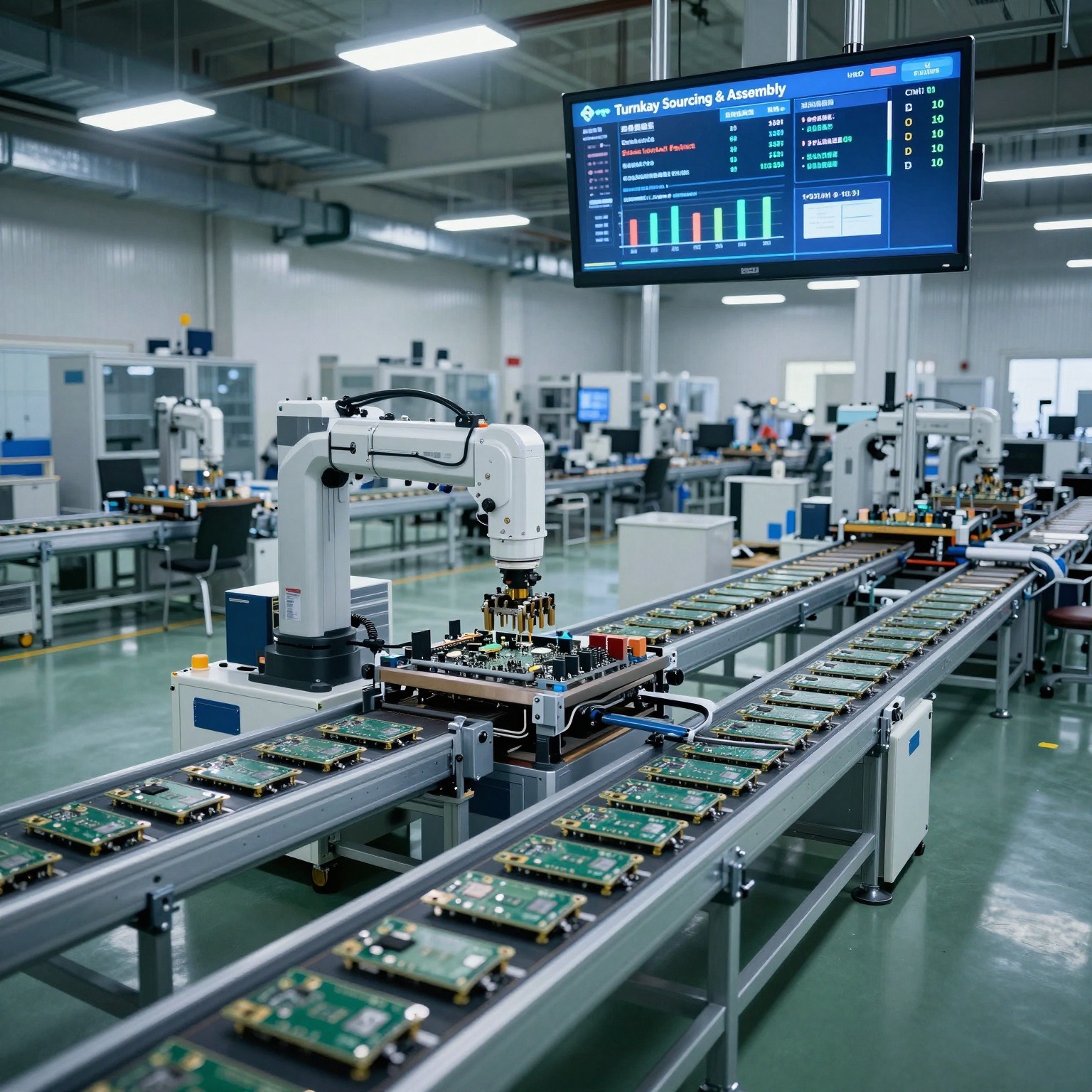

One of the most effective ways to streamline sourcing is by partnering with a manufacturer that offers integrated services. A PCB assembly manufacturer with in-house component sourcing capabilities can handle procurement, verification, and logistics as part of a turnkey solution.

This integration eliminates the need for separate vendor management, reduces errors, and accelerates production timelines. For instance, companies offering electronic component sourcing as part of their service portfolio can leverage bulk buying power and established supplier networks to secure better rates.

5. Monitor Market Trends and Forecast Demand

Staying informed about market trends helps anticipate shortages and adjust procurement plans accordingly. Subscribing to industry reports from sources like IHS Markit or IPC provides insights into component availability, pricing forecasts, and emerging technologies.

Implementing demand forecasting models based on historical data and sales projections enables smarter inventory planning and prevents overstocking or stockouts.

The Role of Technology in Modern Sourcing

Digital transformation has revolutionized Cost-Effective Electronic Components Sourcing. Cloud-based procurement platforms now enable real-time collaboration between design, engineering, and procurement teams.

Artificial intelligence (AI) and machine learning algorithms analyze vast datasets to predict price movements, detect potential obsolescence, and recommend optimal substitutes. Some systems even automate purchase order generation when inventory drops below predefined thresholds.

Moreover, blockchain technology is being explored to enhance transparency and traceability in the component supply chain, ensuring every part’s origin and history are verifiable—critical for aerospace, medical, and defense applications.

Building Long-Term Supplier Relationships

Beyond transactions, successful Cost-Effective Electronic Components Sourcing relies on strong relationships. Engaging in open communication with suppliers fosters trust and collaboration. Regular reviews, feedback loops, and joint problem-solving can lead to customized solutions, early access to new components, and preferential treatment during constrained markets.

Consider signing long-term agreements (LTAs) with key suppliers. These contracts often lock in favorable pricing and guaranteed supply volumes, protecting against market volatility.

Also, attend industry events like electronica or CES to meet suppliers face-to-face, explore new innovations, and strengthen partnerships.

Ensuring Quality Without Sacrificing Cost

It’s crucial to remember that cost-effectiveness should never come at the expense of quality. Implementing rigorous quality control processes—from incoming inspection to final testing—ensures that every component meets specifications.

Look for manufacturers who follow international standards such as ISO 9001, IPC-A-610, and RoHS compliance. These certifications reflect a commitment to consistent quality and environmental responsibility.

For high-reliability applications, consider additional testing methods like X-ray inspection, automated optical inspection (AOI), and thermal cycling to validate component integrity.

A comprehensive guide to quality assurance practices can be found in resources discussing the 6-step quality control process, which outlines best practices for maintaining consistency throughout production.

Case Study: How a Mid-Sized IoT Company Reduced Costs by 30%

An Internet of Things (IoT) device manufacturer was struggling with rising component costs and frequent delays due to reliance on single-source sensors and microcontrollers. By adopting a structured approach to Cost-Effective Electronic Components Sourcing, they achieved significant improvements:

- Redesigned their BOM to use pin-compatible, off-the-shelf alternatives.

- Partnered with a contract manufacturer offering turnkey assembly and sourcing.

- Implemented dual-sourcing for all critical components.

- Automated procurement workflows using cloud-based BOM tools.

Within six months, they reduced component costs by 30%, cut lead times by 40%, and improved on-time delivery rates to 98%.

Their success demonstrates that strategic sourcing, supported by the right tools and partnerships, delivers measurable ROI.

Final Thoughts: Make Sourcing a Strategic Advantage

Cost-Effective Electronic Components Sourcing is not just a back-office function—it’s a strategic lever that drives innovation, competitiveness, and profitability. By integrating sourcing into the design process, leveraging technology, building strong supplier relationships, and partnering with capable manufacturers, companies can navigate today’s complex landscape with confidence.

Whether you’re developing a prototype or managing large-scale production, taking a proactive, informed approach to procurement ensures your projects stay on time, on budget, and built to last.

To learn more about how professional sourcing services can benefit your next project, explore our electronic components sourcing guide, which covers best practices, risk mitigation, and real-world examples.

If you're ready to streamline your supply chain and reduce costs, consider reaching out to experts who specialize in integrated manufacturing and sourcing solutions. You can contact PCB manufacturer for a consultation or get a PCB quote tailored to your needs.