BOM Electronic Components Sourcing for Efficient PCB Assembly

Rosannie Rolling

In the fast-evolving world of electronics manufacturing, one critical step often determines the success or failure of a product launch: BOM electronic components sourcing. Whether you're developing a prototype or scaling up for mass production, the process of acquiring the right components at the right time and cost hinges on a well-executed strategy for BOM (Bill of Materials) electronic components sourcing.

This comprehensive guide explores what BOM electronic components sourcing entails, why it's vital, common challenges, and how partnering with the right PCB assembly services provider can streamline your journey from design to delivery.

What Is BOM Electronic

Components Sourcing?

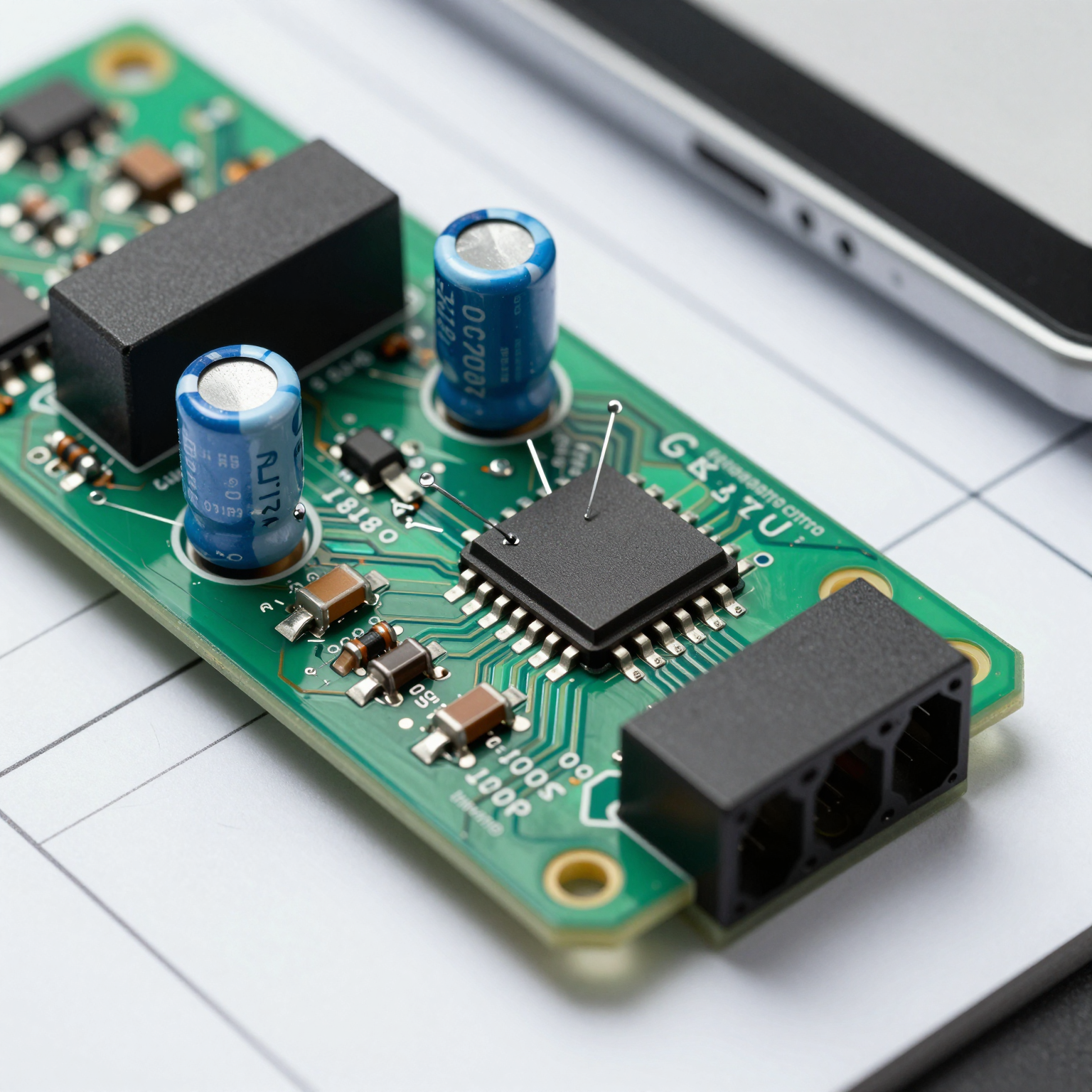

At its core, BOM electronic components sourcing refers to the systematic procurement of all electronic parts listed in a Bill of Materials required to assemble a printed circuit board (PCB). The BOM is a detailed inventory that includes every component—resistors, capacitors, integrated circuits (ICs), connectors, and more—along with specifications such as part numbers, quantities, tolerances, packaging types, and manufacturer preferences.

Effective BOM electronic components sourcing goes beyond simply buying parts. It involves:

- Validating component availability and lifecycle status

- Ensuring compliance with industry standards (e.g., RoHS, REACH)

- Managing lead times and pricing fluctuations

- Identifying alternatives for obsolete or hard-to-find parts

- Coordinating logistics and quality assurance

Without a strategic approach, even a perfectly designed PCB can stall due to missing components or unexpected delays.

Why BOM Electronic Components Sourcing Matters

1. Ensures Design-to-Manufacturing Continuity

A seamless transition from PCB design to production depends heavily on accurate and actionable BOM data. Incomplete or inaccurate BOMs can result in incorrect parts being ordered, leading to assembly errors, rework, and costly project delays.

Strategic BOM electronic components sourcing validates each component against real-world availability, ensuring that what’s on paper can actually be built.

2. Reduces Time-to-Market

Time is a competitive advantage in electronics. Delays caused by component shortages or long lead times can push back product launches by weeks—or even months.

Proactive sourcing allows manufacturers to lock in supply early, use alternative parts when necessary, and maintain momentum throughout the production cycle.

3. Controls Costs and Budget Overruns

Component prices fluctuate based on demand, geopolitical factors, and supply chain disruptions. For example, during the global semiconductor shortage of 2020–2023, some IC prices increased tenfold.

By leveraging forecasting tools and supplier networks, professional BOM electronic components sourcing helps identify cost-effective alternatives without compromising performance.

4. Enhances Supply Chain Resilience

Modern electronics rely on complex global supply chains. A single component sourced from a single factory can become a bottleneck if that facility faces disruption.

Diversified sourcing strategies—including multi-sourcing, last-time buys, and authorized distributors—help mitigate risks associated with obsolescence, natural disasters, or trade restrictions.

Key Challenges in BOM Electronic Components Sourcing

Despite its importance, BOM electronic components sourcing presents several challenges that engineering and procurement teams must navigate.

1. Component Obsolescence

Electronic components have finite lifecycles. Manufacturers often discontinue older models to make way for newer technologies. When a critical component becomes obsolete, it can halt production unless suitable replacements are found quickly.

Solution: Work with partners who monitor lifecycle statuses and offer end-of-life (EOL) notifications and last-time buy recommendations.

2. Counterfeit Parts Risk

The electronics industry faces a persistent threat from counterfeit components—fake or recycled parts sold as new. These can fail prematurely, cause system malfunctions, or pose safety hazards.

According to the U.S. Department of Commerce, counterfeit electronics infiltrate both commercial and defense supply chains, costing billions annually[^1].

Solution: Source exclusively through authorized distributors or certified brokers, and implement rigorous incoming inspection processes.

3. Long Lead Times and Allocation

High-demand components—especially advanced semiconductors—are often subject to allocation, where suppliers ration limited stock among customers. This can extend lead times from weeks to over a year.

For instance, microcontrollers used in automotive and IoT devices have faced extended wait periods due to surging demand and fab capacity constraints.

Solution: Early engagement with suppliers, strategic inventory planning, and design flexibility allow teams to adapt faster.

4. Incomplete or Inaccurate BOMs

An incomplete BOM lacking full part numbers, manufacturer details, or alternate options complicates sourcing efforts. Engineers may specify ideal parts without checking availability.

Best Practice: Use standardized BOM templates and collaborate early with contract manufacturers to validate component choices before finalizing designs.

Best Practices for Effective BOM Electronic Components Sourcing

To overcome these challenges, companies should adopt a structured approach to BOM electronic components sourcing. Here are proven best practices:

1. Start Early – Involve Your CM During Design

Engage your contract manufacturer (CM) early in the design phase. Many CMs offer design-for-manufacturability (DFM) reviews and can flag potential sourcing issues before they arise.

For example, suggesting a commonly available resistor package instead of a rare size can prevent future headaches.

2. Maintain a Preferred Components List (PCL)

Develop a library of pre-qualified, frequently used components known for reliability, availability, and cost-effectiveness. A PCL reduces dependency on single-source parts and speeds up future designs.

3. Leverage Dual-Sourcing and Alternatives

Whenever possible, design with dual-sourced components or include approved alternates in the BOM. This provides flexibility during shortages.

For instance, specifying both a Texas Instruments and an Analog Devices op-amp with identical specs allows substitution without redesign.

4. Partner with Experts in Component Sourcing

Outsourcing BOM electronic components sourcing to experienced providers offers significant advantages. Reputable CMs like Suntop Electronics combine deep supplier relationships, market intelligence, and logistics expertise to secure components efficiently.

Their electronic component sourcing teams handle everything from RFQs to customs clearance, freeing engineers to focus on innovation.

5. Monitor Market Trends and Forecast Demand

Stay informed about global trends affecting component availability. Subscribe to industry reports, track geopolitical developments, and use predictive analytics to anticipate shortages.

Organizations like IPC (Association Connecting Electronics Industries) publish regular market trend reports that help forecast supply conditions.

6. Utilize Inventory Management Tools

Implement digital systems to manage component inventories, track usage, and automate reorder points. Cloud-based platforms integrate with ERP and PLM systems for real-time visibility across the supply chain.

How Turnkey Solutions Simplify BOM Electronic Components Sourcing

Turnkey PCB assembly services take full responsibility for BOM electronic components sourcing, offering a complete solution from component procurement to finished board delivery.

With turnkey support:

- You provide the BOM and Gerber files

- The CM sources all components, performs quality checks, assembles the boards, and tests them

- Final products are shipped ready for integration

This model is especially beneficial for startups, small businesses, or companies lacking dedicated procurement teams.

It also aligns with agile development cycles, enabling rapid prototyping and scalable production runs—all under one roof.

The Role of Quality Assurance in Component Sourcing

Even with perfect sourcing, quality cannot be assumed. Every batch of components must undergo verification to ensure authenticity and functionality.

Reputable providers employ multiple QA steps:

- Visual inspection under magnification

- X-ray analysis for hidden defects (e.g., in BGAs)

- Electrical testing using sample units

- Traceability documentation (lot numbers, date codes, certificates of compliance)

These measures protect against counterfeits and ensure consistent product performance.

Learn more about our 6-step quality control process that safeguards every stage of production.

Conclusion: Optimize Your BOM Electronic Components Sourcing Strategy

BOM electronic components sourcing is not just a logistical task—it’s a strategic function that impacts product quality, cost, and time-to-market. As electronics grow more complex and supply chains more volatile, having a robust sourcing plan is essential.

By adopting best practices, leveraging expert partners, and integrating sourcing into the early stages of product development, companies can build resilient, efficient, and scalable manufacturing operations.

Whether you’re launching your first prototype or managing high-volume production, don’t underestimate the power of smart BOM electronic components sourcing.

Ready to streamline your next project? Get a PCB quote today and discover how professional sourcing and assembly services can accelerate your path to market.