Turnkey PCB Assembly: The Complete Process and Expert Tips

Rossannie Rolling

What Is Turnkey PCB Assembly?

In modern electronics manufacturing, Turnkey PCB Assembly has become a go-to solution for companies aiming to streamline their product development and reduce time-to-market. Unlike traditional PCB assembly models where clients handle component sourcing and logistics, Turnkey PCB Assembly is a comprehensive service that covers every step—from design review and material procurement to final testing and delivery.

This end-to-end approach means that once you provide your design files (Gerber, BOM, etc.), the manufacturer manages everything else. Whether you're working with standard rigid boards or advanced designs like Turnkey FPC Assembly, Turnkey Rigid-Flex PCB Assembly, or Turnkey HDI PCB Assembly, this model simplifies coordination and improves overall efficiency.

For startups, engineering teams, and OEMs alike, adopting a turnkey strategy reduces overhead, minimizes errors, and ensures faster turnaround—making it ideal for both prototyping and high-volume production.

The Full Turnkey PCB Assembly Process

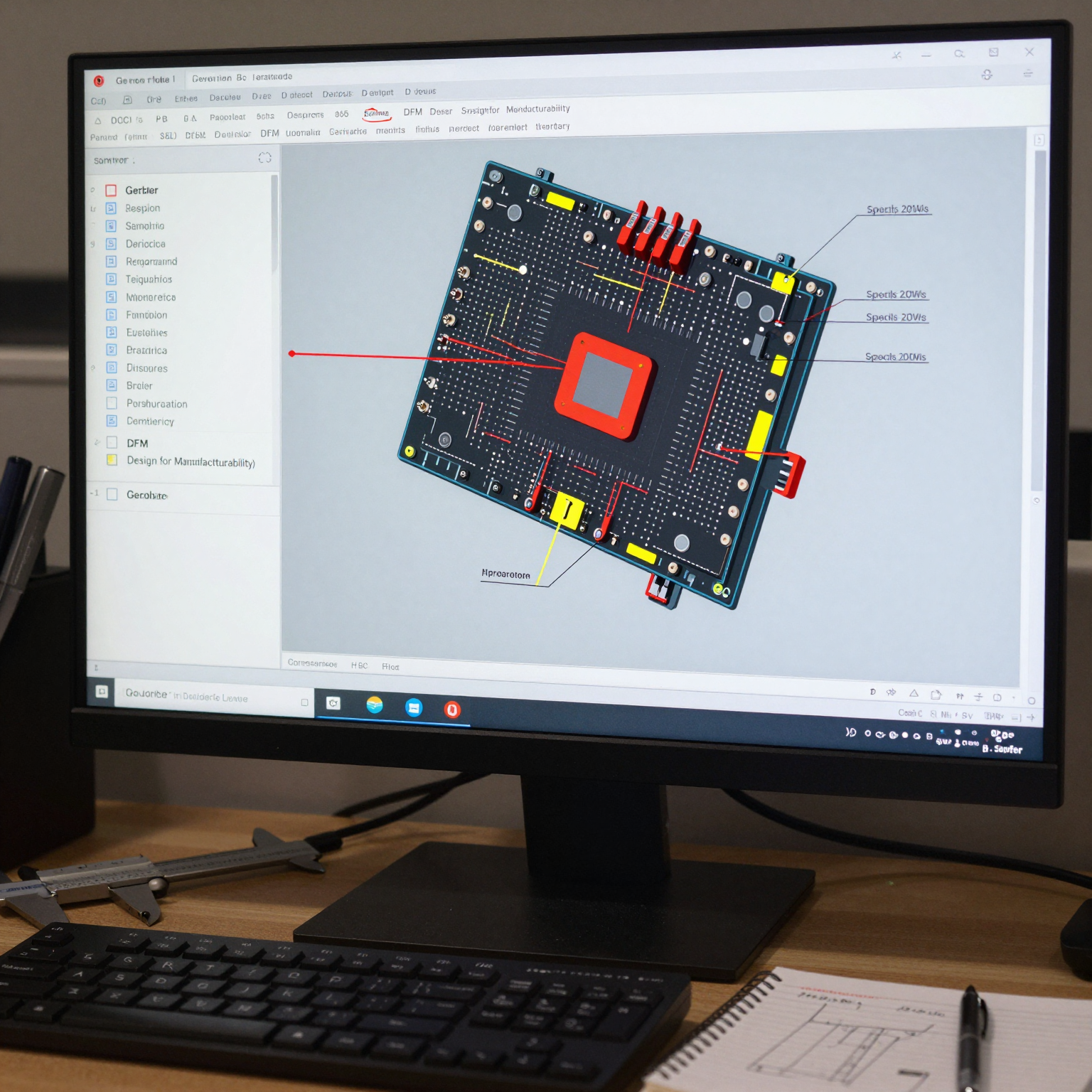

Step 1: Design Review and DFM

Check

The journey begins with a thorough design evaluation. Your manufacturer will conduct a Design for Manufacturability (DFM) analysis to identify potential issues such as trace spacing violations, solder mask slivers, or incorrect footprints. This step is especially critical in complex assemblies like Turnkey HDI PCB Assembly, where microvias, blind/buried vias, and tight pitch components require precision.

Manufacturers often use automated tools alongside expert engineers to ensure compliance with IPC standards. Catching problems early avoids costly rework later.

🔍 Pro Tip: Always submit complete documentation, including Gerber files, Bill of Materials (BOM), pick-and-place files, and any special assembly instructions.

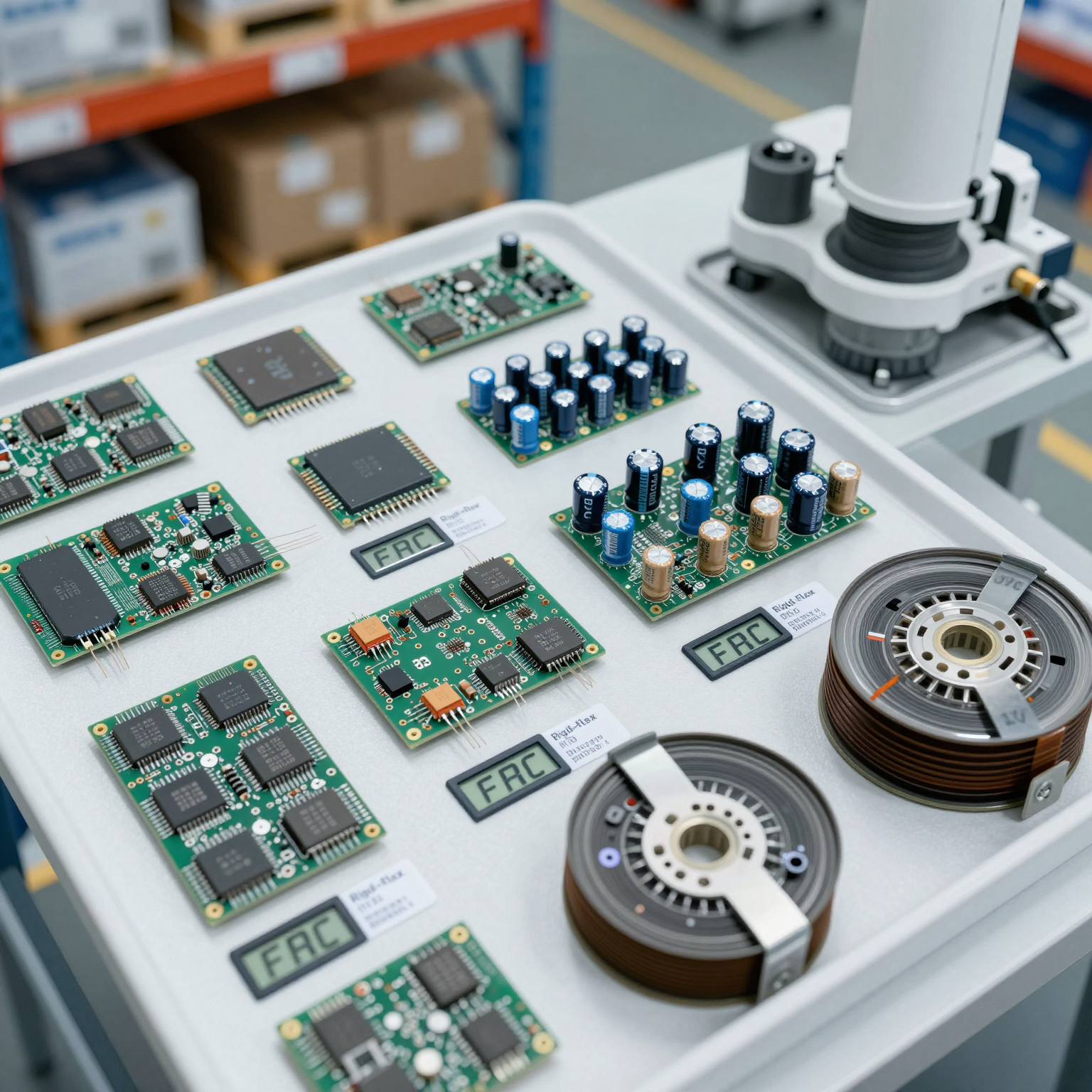

Step 2: Component Sourcing and Procurement

One of the biggest advantages of Turnkey PCB Assembly is that the manufacturer handles electronic component sourcing. This includes verifying part availability, checking for obsolescence, identifying suitable alternates, and negotiating pricing with suppliers.

In cases involving flexible circuits, Turnkey FPC Assembly requires specialized materials such as polyimide films and adhesive layers. Similarly, Turnkey Rigid-Flex PCB Assembly involves sourcing both rigid board laminates and flexible dielectrics, which must be compatible across the stack-up.

Some manufacturers maintain long-term relationships with global distributors and franchised suppliers, ensuring reliable access even during supply chain disruptions. For more insights into how this works, check out our guide on electronic component sourcing.

Step 3: PCB Fabrication

Once components are secured, the bare PCB fabrication process begins. Depending on your project type, this could involve:

- Standard multilayer boards

- Flexible printed circuits (FPC)

- Rigid-flex hybrids

- High-Density Interconnect (HDI) structures

For Turnkey HDI PCB Assembly, advanced techniques like laser drilling, sequential lamination, and via-in-pad technology are employed to achieve higher routing density and improved signal integrity. These boards are commonly used in smartphones, wearables, and medical devices where space and performance are critical.

Quality control at this stage includes impedance testing, AOI (Automated Optical Inspection), and electrical continuity checks.

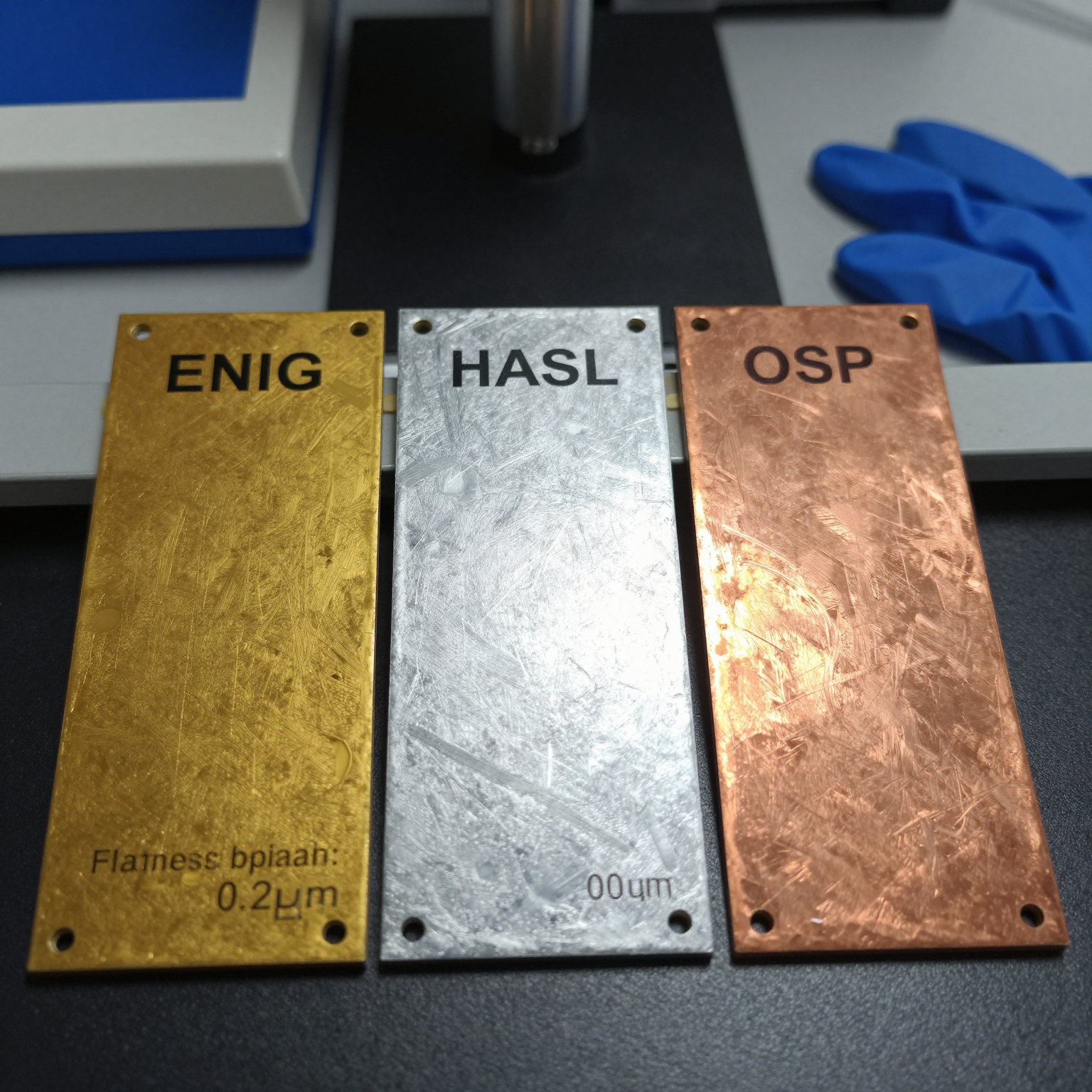

Step 4: Surface Finish Application

Before assembly, PCBs receive a surface finish to protect exposed copper and ensure good solderability. Common finishes include:

- ENIG (Electroless Nickel Immersion Gold)

- HASL (Hot Air Solder Leveling)

- Immersion Silver

- OSP (Organic Solderability Preservative)

Each has trade-offs in cost, shelf life, and compatibility with fine-pitch components. In Turnkey FPC Assembly, ENIG or Immersion Tin are often preferred due to their flatness and reliability in dynamic flexing environments.

Learn more about choosing the right option in our detailed PCB surface finishes guide.

Step 5: Component Placement and Soldering

Now comes the core of the assembly phase: placing and soldering components onto the board.

SMT (Surface Mount Technology)

Most modern assemblies rely heavily on SMT lines, where pick-and-place machines accurately position components as small as 01005 packages. Reflow ovens then melt solder paste to form electrical and mechanical bonds.

For Turnkey HDI PCB Assembly, handling ultra-fine pitch BGAs and CSPs demands high-precision stencils and advanced vision systems.

Through-Hole Technology

While less common today, through-hole components still appear in power electronics and connectors. Wave soldering or manual insertion may be used depending on volume and complexity.

For a deeper comparison between these methods, see our article on SMT vs through-hole assembly.

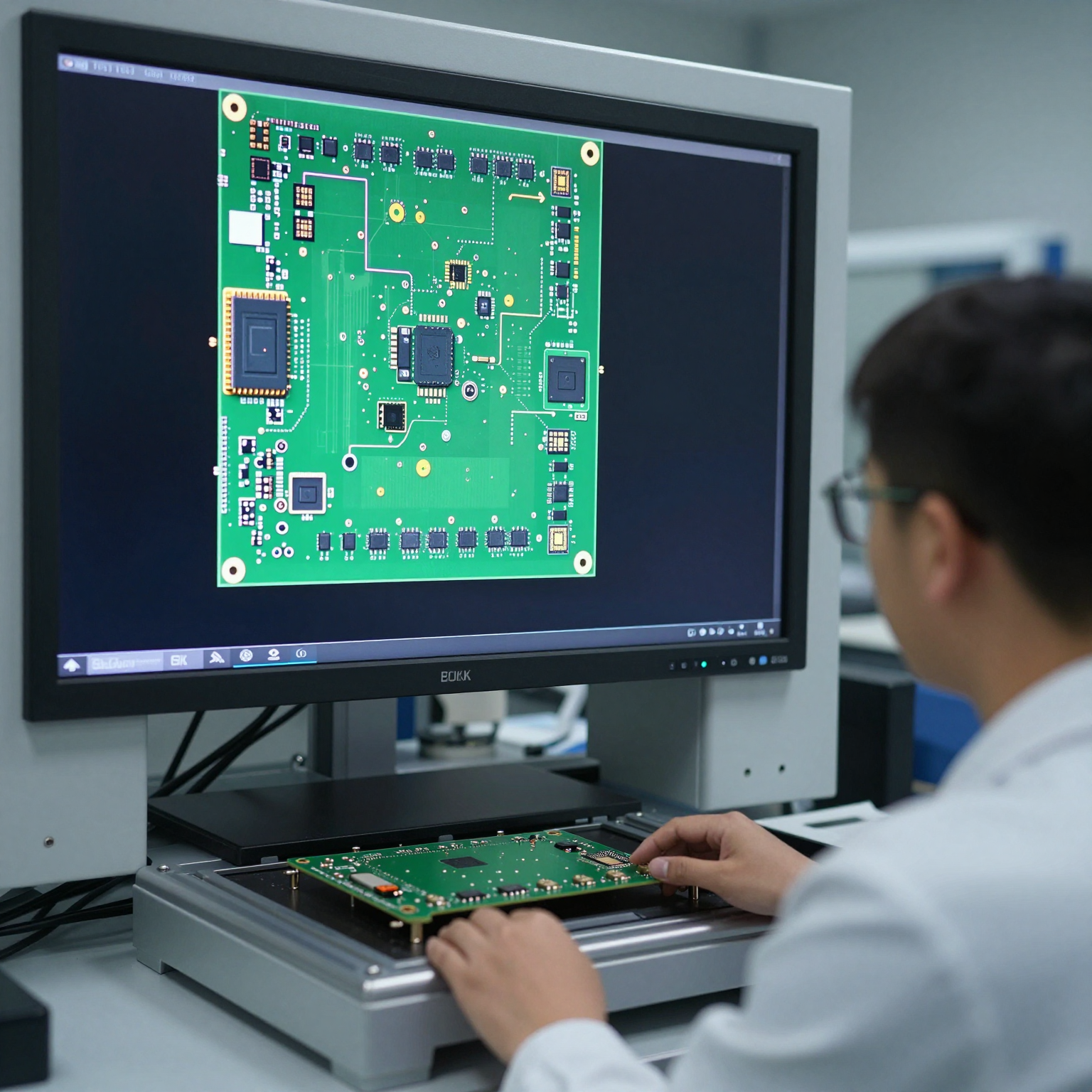

Step 6: Quality Control and Testing

No Turnkey PCB Assembly process is complete without rigorous testing. Common methods include:

- Automated Optical Inspection (AOI): Detects missing, misaligned, or damaged components.

- **X-Ray Inspection:

** Essential for inspecting hidden solder joints under BGAs and in layered rigid-flex boards.

- In-Circuit Testing (ICT): Verifies individual component values and connections.

- Functional Testing: Simulates real-world operation to validate performance.

Many leading providers follow a structured 6-step quality control process to ensure zero-defect delivery.

Step 7: Final Packaging and Delivery

After passing all tests, boards are cleaned (if necessary), conformal coated (for harsh environments), labeled, and packaged according to customer specifications. The finished units are then shipped directly to your facility or distribution center—truly a “turn the key and go” experience.

Why Choose Turnkey Over Kitted Assembly?

You might wonder: why not just supply your own components (kitted model)? While kitting gives you full control over sourcing, it also transfers risk and responsibility to your team.

With Turnkey PCB Assembly, benefits include:

- Reduced lead times: Parallel processing of sourcing and fabrication.

- Lower total cost: Bulk purchasing power and reduced logistics overhead.

- Better risk management: Manufacturers can suggest substitutes if parts are obsolete or backordered.

- Single point of accountability: One vendor handles quality, traceability, and delivery.

This makes turnkey ideal for companies without dedicated procurement departments or those entering new markets quickly.

Expert Tips for a Successful Turnkey Project

1. Provide a Clean, Detailed BOM

Your Bill of Materials should include:

- Manufacturer Part Numbers (MPNs)

- Alternate part options (if acceptable)

- Reference designators

- Tolerance and RoHS compliance info

Avoid vague entries like “resistor 10k”—be specific.

2. Use Standard Components When Possible

Custom or obsolete parts increase cost and delay timelines. Stick to widely available components unless absolutely necessary.

3. Design with Assembly in Mind

Follow best practices such as:

- Maintaining adequate clearance around sensitive components

- Orienting similar components in the same direction

- Avoiding shadowed areas in mixed-technology boards

For flexible designs, refer to our flexible PCB design best practices guide.

4. Communicate Special Requirements Early

Need conformal coating? Potting? Burn-in testing? Specify these upfront so they can be factored into planning and quoting.

5. Leverage Manufacturer Expertise

Reputable partners don’t just build—they consult. Take advantage of free DFM feedback and value engineering suggestions to optimize your design before production.

Applications Across Industries

Turnkey PCB Assembly serves a broad range of sectors:

- Medical Devices: Where reliability and regulatory compliance are paramount. Rigid-flex and HDI boards enable compact, implantable, or wearable tech.

- Consumer Electronics: Fast-paced innovation demands rapid iteration—perfect for turnkey speed and scalability.

- Aerospace & Defense: Requires strict adherence to MIL specs and traceability, which top-tier turnkey providers support.

- Industrial Automation: Long-lifecycle products benefit from stable component sourcing and long-term manufacturability.

Companies serving these fields often highlight their industries served by PCB manufacturer to demonstrate domain expertise.

Choosing the Right Turnkey Partner

Not all PCB assembly manufacturer services are created equal. Look for:

- Certifications (ISO 9001, IPC-A-610, UL, etc.)

- In-house capabilities (fabrication, assembly, testing)

- Transparent communication and reporting

- Scalability from prototype to mass production

Visit the about PCB assembly company page of potential vendors to assess their experience, team, and values.

Also, evaluate their PCB manufacturing capabilities to confirm they can handle your specific needs—especially for advanced technologies like Turnkey FPC Assembly or Turnkey Rigid-Flex PCB Assembly.

Getting Started with Your Turnkey Project

Ready to begin? Start by preparing your design package and reaching out for a quote. Most manufacturers offer fast response times, especially if your files are complete.

To get started today, you can get a PCB quote or directly contact PCB manufacturer representatives for personalized assistance.

Whether you're building a single prototype or launching a global product line, Turnkey PCB Assembly offers a smarter, faster path to market—with fewer headaches and greater confidence in quality.