Turnkey PCB Assembly with Electronic Components Sourcing: A Complete Guide

Winnie King

In today’s fast-paced electronics industry, speed, reliability, and cost-efficiency are non-negotiable. Whether you're developing a prototype or scaling up to mass production, managing the Printed Circuit Board (PCB) fabrication and assembly process can be complex—especially when dealing with component procurement, quality control, and logistics. This is where Turnkey PCB Assembly combined with professional Electronic Components Sourcing becomes a game-changer.

By outsourcing both the manufacturing and sourcing aspects to a single provider, companies can significantly reduce lead times, minimize risks, and focus on innovation rather than operational bottlenecks. In this comprehensive guide, we’ll explore what turnkey PCB assembly entails, why electronic components sourcing matters, and how integrating both services benefits your business.

What Is Turnkey PCB Assembly?

Defining the Turnkey Model

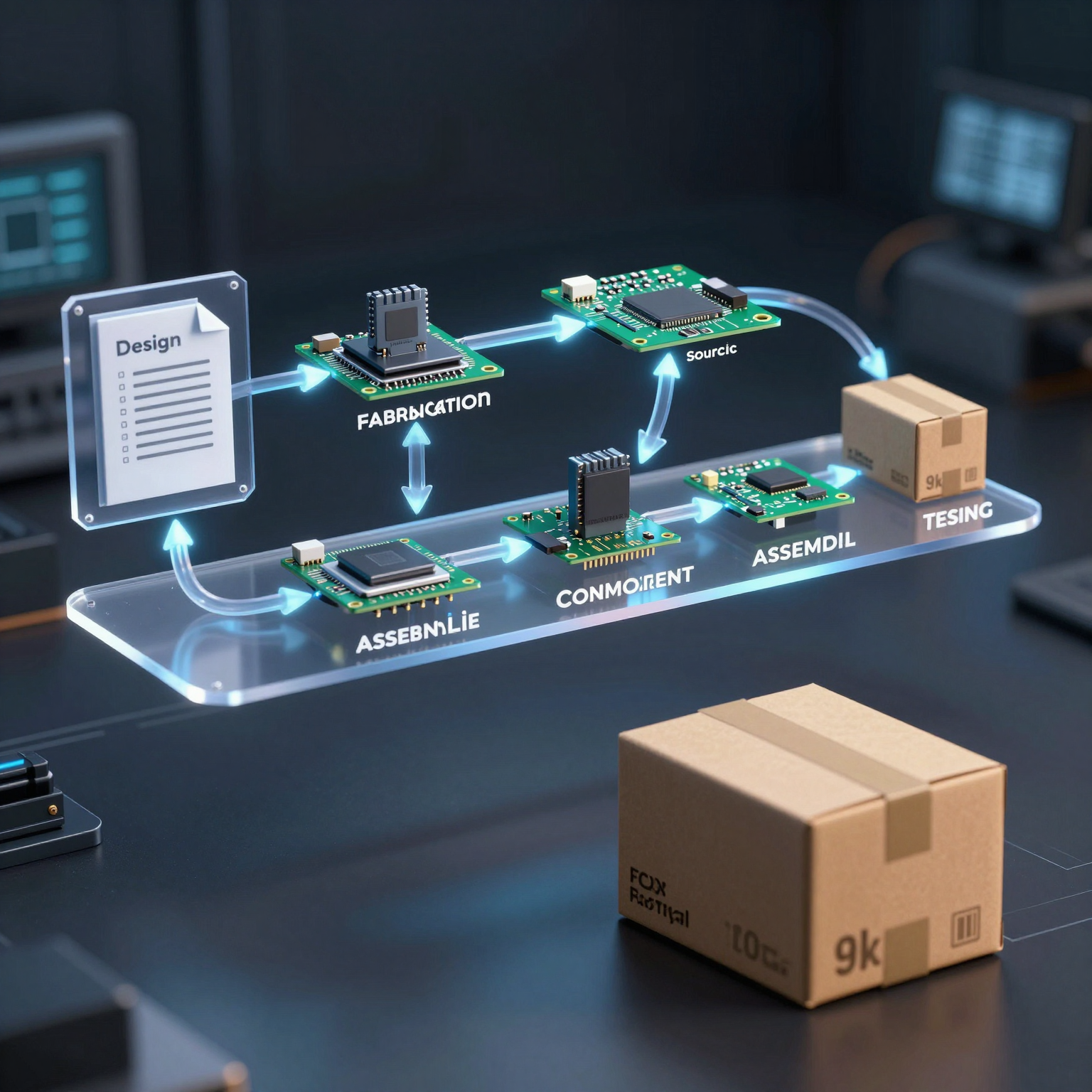

Turnkey PCB Assembly refers to a complete end-to-end service in which a manufacturer handles every step of the PCB production process—from bare board fabrication and component sourcing to final assembly, testing, and delivery. As the name suggests, clients “turn the key” and receive fully functional circuit boards ready for integration into their end products.

This model contrasts with partial or consignment models, where customers must supply components themselves or manage certain stages of the process independently. The turnkey approach simplifies project management by placing responsibility for quality, timing, and coordination in the hands of one trusted partner.

Key Stages in Turnkey PCB Assembly

A typical turnkey process includes:

- Design Review & DFM Check – Ensuring the PCB layout is manufacturable.

- Bare PCB Fabrication – Manufacturing the physical board based on Gerber files.

- Electronic Components Sourcing – Procuring all required parts from verified suppliers.

- PCB Assembly (SMT + Through-Hole) – Placing and soldering components using automated or manual techniques.

- Quality Testing – Conducting AOI, X-ray inspection, functional tests, etc.

- Final Packaging & Delivery – Shipping completed assemblies directly to the client.

Each stage is tightly integrated, reducing handoff delays and communication gaps between different vendors.

Why Electronic Components Sourcing Matters

The Hidden Complexity Behind Component Procurement

While designing a PCB may take weeks, sourcing reliable components can take months—especially in times of global shortages, long lead times, or obsolescence issues. Engineers often underestimate the challenges involved in Electronic Components Sourcing, such as:

- Verifying authenticity and avoiding counterfeit parts

- Managing minimum order quantities (MOQs)

- Navigating supply chain volatility

- Ensuring compliance with RoHS, REACH, and other regulations

- Handling last-time buys for obsolete components

Without expertise, these hurdles can delay projects, increase costs, or compromise product quality.

How Professional Sourcing Adds Value

When a PCB assembly manufacturer offers in-house sourcing capabilities, they bring several advantages:

- Access to Global Supply Networks: Established relationships with authorized distributors and franchised suppliers ensure genuine parts at competitive prices.

- Substitution Expertise: When original components are unavailable, experienced teams can recommend drop-in replacements that meet electrical and mechanical specs.

- Inventory Management: Some providers maintain strategic stockpiles of commonly used components to mitigate supply disruptions.

- Cost Optimization: Bulk purchasing power and alternative sourcing strategies help reduce overall BOM (Bill of Materials) costs.

For example, during the 2020–2022 semiconductor shortage, companies relying on external sourcing partners were more likely to maintain production continuity compared to those managing procurement internally.

According to a report by Deloitte, supply chain resilience has become a top priority for electronics manufacturers, with many turning to integrated sourcing solutions to improve agility.

Benefits of Combining Turnkey PCB Assembly with Component Sourcing

1. Faster Time-to-Market

One of the most significant advantages is accelerated development cycles. With all processes under one roof, there's no need to coordinate between multiple vendors. Design validation, component acquisition, and assembly proceed in parallel whenever possible.

Startups and innovators benefit especially—getting prototypes built quickly allows for faster user testing and iteration before full-scale launch.

2. Reduced Operational Burden

Managing separate contracts with fabricators, assemblers, and component suppliers requires extensive administrative work. With turnkey services, you deal with just one point of contact throughout the entire lifecycle.

This consolidation reduces email chains, eliminates blame-shifting if something goes wrong, and streamlines documentation like invoices, shipping labels, and compliance certificates.

3. Improved Quality Control

Integrated workflows allow for tighter quality oversight. For instance, if a batch of capacitors fails incoming inspection, the sourcing team can immediately initiate a replacement order while the assembly line adjusts its schedule—without requiring customer intervention.

Moreover, consistent handling across stages minimizes damage risks and ensures traceability from raw materials to finished goods.

4. Cost Predictability

With a fixed quote covering everything—including components—budget forecasting becomes easier. There are fewer surprises due to unexpected price hikes or shipping fees because the provider absorbs or manages those variables upfront.

Some providers even offer locked-in pricing for specific volumes, giving businesses financial stability over longer production runs.

5. Scalability Without Overhead

Whether producing 50 units for field trials or 50,000 units for retail distribution, turnkey services scale seamlessly. You don’t need to invest in warehouse space, procurement staff, or inventory systems.

This flexibility supports agile manufacturing strategies, allowing companies to respond rapidly to market demand without capital expenditure.

Who Should Use Turnkey PCB Assembly?

Ideal Candidates

Turnkey solutions are particularly beneficial for:

- Startups and SMEs lacking dedicated supply chain teams

- Engineering R&D Departments focused on design, not logistics

- Consumer Electronics Brands launching new devices annually

- Medical and Industrial Equipment Makers requiring high-reliability assemblies

- IoT Developers needing small-batch, frequent iterations

Even large enterprises use turnkey services for non-core products or overflow capacity, freeing internal resources for mission-critical initiatives.

When Consignment Might Be Better

There are exceptions. Some organizations prefer consignment models when:

- They already have exclusive contracts with component suppliers

- Security-sensitive designs require strict control over part origins

- Legacy systems use proprietary or custom-manufactured components

However, even in these cases, hybrid models exist—where standard parts are sourced by the manufacturer and sensitive items are provided by the client.

Choosing the Right Partner for Turnkey Services

Not all providers deliver the same level of service. To ensure success, evaluate potential partners based on:

1. Technical Capabilities

Can they handle your board complexity? Look for experience with:

- High-Density Interconnect (HDI) boards

- Mixed-technology assemblies (SMT + through-hole)

- Fine-pitch components and BGAs

- Flexible and rigid-flex PCBs

Review their PCB manufacturing capabilities to confirm compatibility with your design requirements.

2. Supply Chain Transparency

Ask about their sourcing policies:

- Do they use only authorized distributors?

- How do they verify component authenticity?

- Can they provide lot traceability and certificates of conformance (CoC)?

Transparency builds trust and helps meet regulatory standards in industries like aerospace, automotive, and healthcare.

3. Quality Assurance Processes

Robust QA protocols are essential. Inquire about:

- Incoming material inspection procedures

- In-process testing methods (e.g., AOI, SPI, ICT)

- Final functional testing capabilities

- Compliance with IPC-A-610 and J-STD-001 standards

A well-documented 6-step quality control process indicates a commitment to excellence.

4. Customer Support and Communication

Responsive account management makes a big difference. Ensure the provider offers:

- Dedicated project managers

- Regular progress updates

- Clear escalation paths for issues

- Fast turnaround on quotes and technical queries

You should feel confident reaching out at any stage of the project.

Real-World Applications

Case Study: IoT Smart Sensor Development

An environmental tech startup needed to produce 2,000 wireless air quality sensors within three months. Their design included Bluetooth modules, MEMS sensors, and a custom microcontroller—all subject to tight supply constraints.

By partnering with a turnkey provider offering electronic component sourcing, they avoided six-week delays on critical ICs through smart substitutions and alternate packaging options. The entire batch was delivered on time, enabling them to meet investor milestones and secure follow-on funding.

Case Study: Medical Device Manufacturer

A diagnostics company required Class II medical-grade PCBs with stringent reliability standards. Using a turnkey model allowed them to offload component vetting and first-article testing, focusing instead on clinical validation and FDA submissions.

The result? A 40% reduction in pre-production timeline and full compliance with ISO 13485 requirements.

Getting Started with Turnkey PCB Assembly

Ready to simplify your electronics manufacturing? Here’s how to begin:

-

Prepare Your Design Files

Gather Gerber files, BOM (Bill of Materials), pick-and-place data, and any special instructions. -

Request a Quote

Submit your package to a qualified provider. Many offer online tools for instant estimates. -

Engage in Pre-Production Review

Participate in DFM/DFA feedback sessions to catch errors early. -

Approve Components and Schedule

Confirm substitutions (if needed) and agree on delivery timelines. -

Receive and Test First Units

Inspect prototypes for functionality and fit before approving full production.

For expert support, consider contacting a trusted PCB assembly manufacturer with proven experience in turnkey solutions.