Choosing the Right PCB Assembly House: A Comprehensive Guide for Modern Electronics Manufacturing

Rachel Roland

In today’s fast-evolving electronics landscape, bringing a product from concept to market hinges not just on innovative design but also on reliable, high-quality manufacturing. At the heart of this process lies one critical decision: selecting the right PCB Assembly House.

But what exactly is a PCB Assembly House? Often referred to as a PCBA (Printed Circuit Board Assembly) manufacturer or an EMS (Electronic Manufacturing Services) provider, a PCB Assembly House is more than just a factory that solders components onto circuit boards. It's a strategic partner responsible for transforming bare PCBs into fully functional electronic assemblies—often handling everything from component sourcing and quality assurance to final testing and logistics.

For engineers, startups, OEMs, and product developers, understanding the core capabilities and offerings of a modern PCB Assembly House is essential. This guide breaks down the five key dimensions that define a top-tier PCB Assembly House, helping you make an informed choice based on your specific project requirements.

1. Manufacturing Capabilities: Matching Technology to Your Design Needs

The first—and perhaps most technical—consideration when evaluating a PCB Assembly House is whether its hardware, equipment, and processes can handle your board’s complexity. Not all factories are created equal, and mismatched capabilities can lead to yield issues, delays, or even complete project failure.

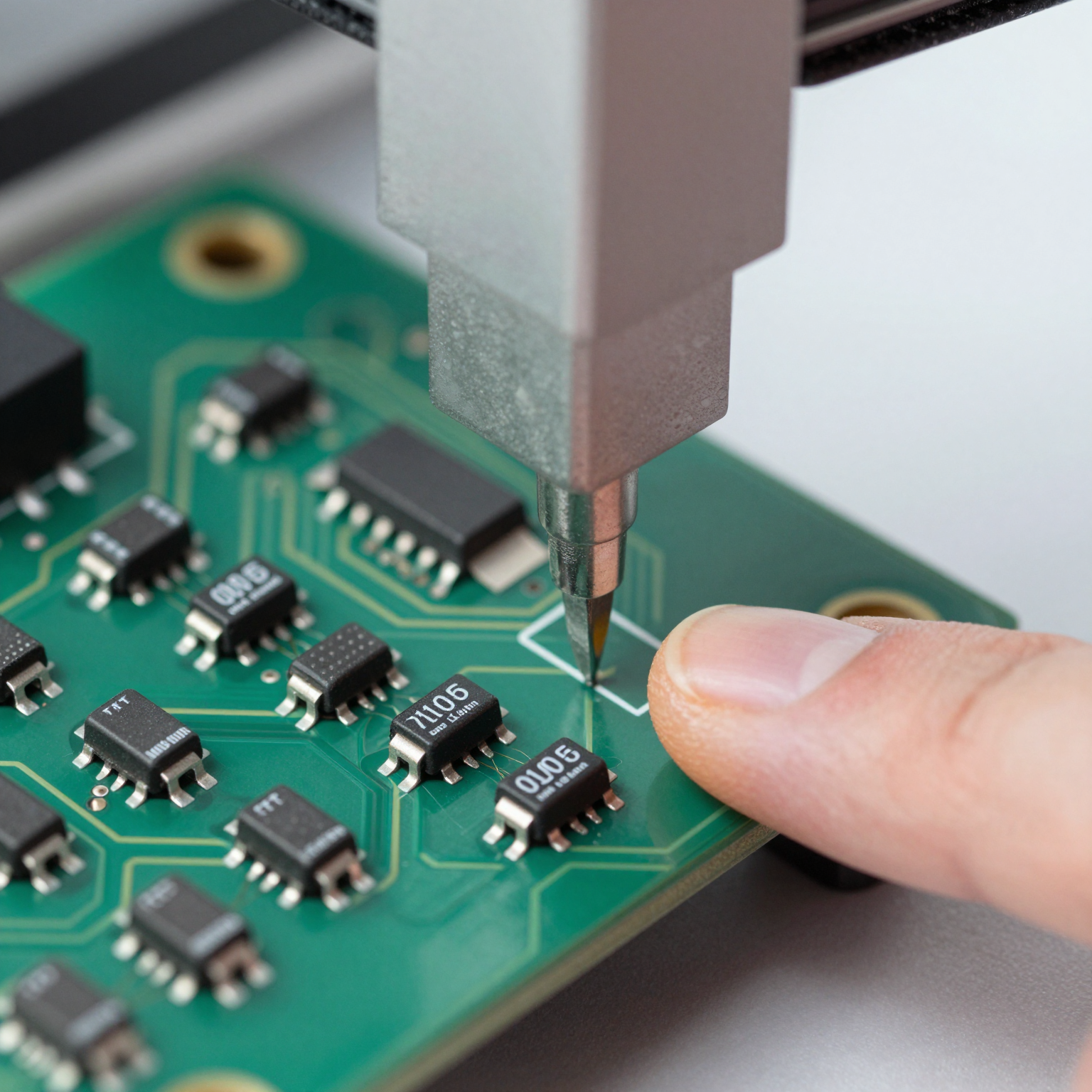

Precision SMT and Assembly

Component Handling

Modern electronics demand miniaturization. Components like 0201, 01005, and even smaller micro-chips require advanced Surface Mount Technology (SMT) lines with ultra-fine pitch placement accuracy.

A capable PCB Assembly House should offer:

- High-speed, high-precision pick-and-place machines with vision systems capable of placing sub-millimeter components.

- Support for fine-pitch ICs and QFN packages with pitches below 0.4mm.

- Experience with passive components as small as 01005 (0.4mm x 0.2mm).

If your design includes Ball Grid Arrays (BGAs), Chip Scale Packages (CSPs), or other bottom-termination components, ensure the PCB Assembly House has both the capability to assemble them and the tools to inspect and rework them effectively.

🔍 Tip: Ask about their smallest supported component size and BGA pitch tolerance before committing.

Process Flexibility: SMT,

THT, and Hybrid Assembly

While SMT dominates modern electronics, through-hole technology (THT) remains vital for connectors, transformers, and high-reliability applications.

A well-rounded PCB Assembly House typically supports multiple assembly methods:

- SMT (Surface Mount Technology): For automated, high-density placement.

- THT (Through-Hole Technology): For robust mechanical connections.

- Wave Soldering: Efficient for bulk THT component soldering.

- Selective Soldering: For mixed-technology boards where only certain areas need THT soldering.

- Hand Soldering/Manual Assembly: For low-volume, complex, or sensitive components.

Hybrid boards combining SMT and THT require careful process planning. Ensure your chosen PCB Assembly House has experience managing these workflows without compromising quality.

For deeper insights into these techniques, read our detailed comparison of SMT vs through-hole assembly.

Specialized Board Technologies

Beyond standard FR-4 boards, many applications now use specialized substrates:

- Rigid-Flex PCBs: Combine rigid and flexible sections; common in wearables and aerospace.

- High-Density Interconnect (HDI): Use microvias and blind/buried vias for compact designs.

- Metal-Core PCBs (e.g., Aluminum Base): Ideal for LED lighting and power electronics due to superior thermal dissipation.

- Thick Copper PCBs: Used in high-current applications such as motor drives and industrial power supplies.

Each of these requires unique tooling, lamination cycles, and assembly parameters. A competent PCB Assembly House will have dedicated processes and trained personnel to manage these materials safely and efficiently.

Ensure they can support your specific stack-up, surface finish (e.g., ENIG, Immersion Silver, OSP), and thermal profile requirements.

2. Quality Management & Certifications: The Non-Negotiable Foundation

Quality isn't optional—it's the baseline expectation. When selecting a PCB Assembly House, certifications and inspection protocols serve as proof of a disciplined, repeatable manufacturing system.

Industry Standards: IPC-A-610 and Beyond

The IPC-A-610 standard defines acceptability criteria for electronic assemblies. Most reputable PCB Assembly Houses adhere strictly to this guideline, often targeting Class 2 (Commercial/Industrial) or Class 3 (High-Reliability) depending on application needs.

- Class 1: General consumer electronics with minimal reliability demands.

- Class 2: Computers, telecom, and industrial controls requiring extended life and uninterrupted service.

- Class 3: Medical devices, avionics, military, and automotive systems where failure is not acceptable.

Ask which class your target PCB Assembly House builds to—and verify it through audits or sample inspections.

Additionally, familiarity with J-STD-001 (soldering standards) and IPC-7711/7721 (rework and repair) indicates deep expertise in best practices.

System Certifications: Gateways to Regulated Industries

Certain industries impose additional certification requirements:

- ISO 9001: The foundational quality management system standard. All serious PCB Assembly Houses should be certified.

- IATF 16949: Required for automotive electronics suppliers. Ensures traceability, defect prevention, and continuous improvement across the supply chain.

- ISO 13485: Mandatory for medical device manufacturers. Focuses on risk management, documentation, and regulatory compliance.

- AS9100: Aerospace and defense equivalent of IATF 16949.

These aren’t just badges—they represent rigorous internal controls, supplier management, and customer focus.

If you're developing products for regulated markets, confirm your PCB Assembly House holds the appropriate certifications. Otherwise, you may face audit failures or regulatory roadblocks later.

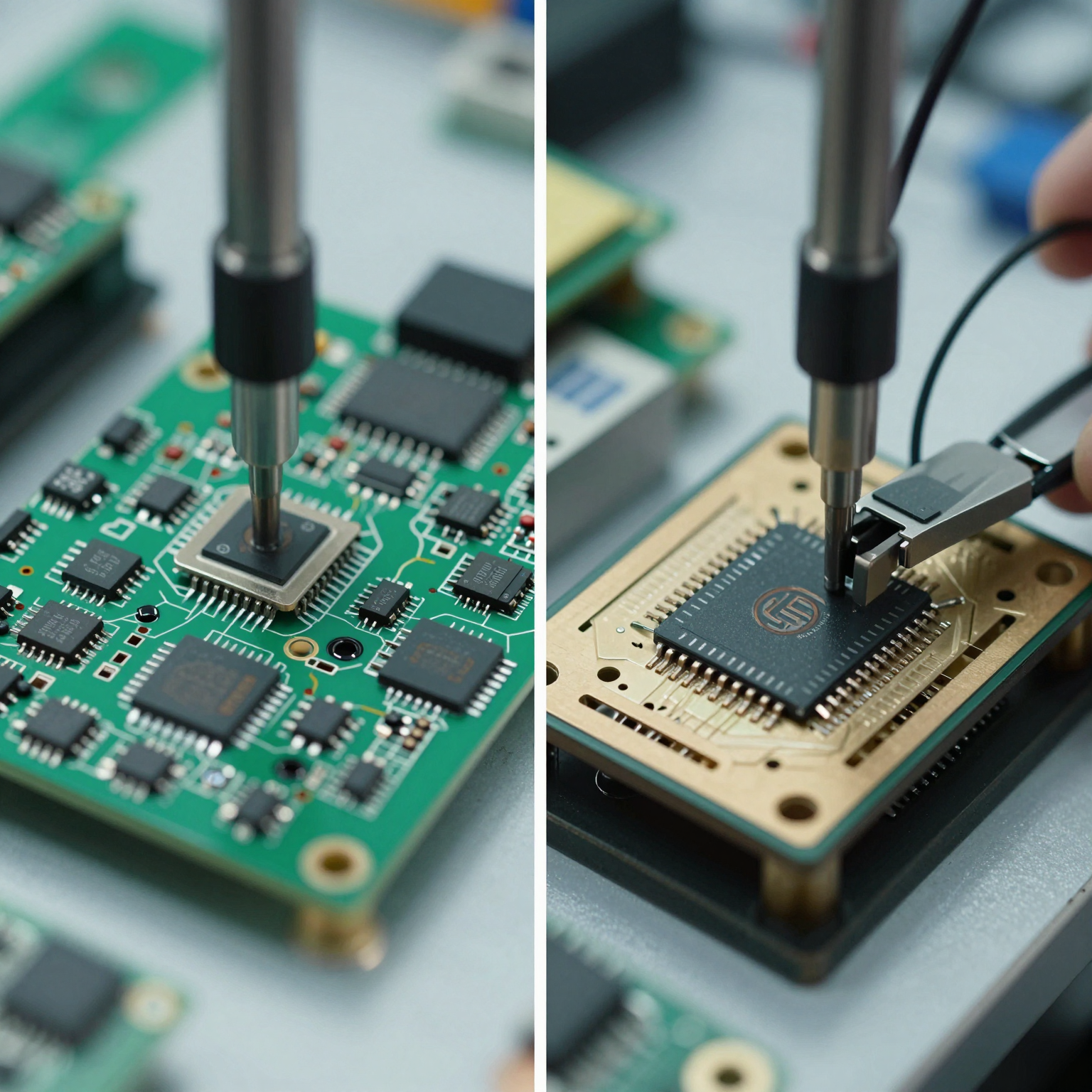

Advanced Inspection & Testing Infrastructure

Even the best processes require verification. A world-class PCB Assembly House invests heavily in automated inspection technologies:

| Tool | Purpose |

|---|---|

| SPI (Solder Paste Inspection) | Verifies correct volume, alignment, and shape of solder paste deposits before component placement. Prevents opens, shorts, and tombstoning. |

| AOI (Automated Optical Inspection) | Detects missing, misaligned, or damaged components after reflow. Also checks polarity and orientation. |

| X-Ray Inspection (AXI) | Essential for inspecting hidden joints under BGAs, CSPs, and shielded components. Reveals voids, bridging, and insufficient solder. |

| ICT (In-Circuit Test) | Electrical test using bed-of-nails fixtures to validate individual component values and connectivity. |

| FCT (Functional Circuit Test) | Simulates real-world operation by powering up the board and running software diagnostics. |

Many leading PCB Assembly Houses integrate these tools into a closed-loop quality system, where data from SPI informs AOI thresholds, and defects trigger immediate corrective actions.

For example, if X-ray reveals excessive voiding in BGA solder balls, the reflow profile can be adjusted automatically. This level of integration separates elite providers from basic contract assemblers.

To learn more about how quality is ensured throughout production, explore our article on the 6-step quality control process.

3. Service Models: Turnkey vs. Consigned – Which Fits Your Business?

Not every company wants—or needs—the same level of outsourcing. A mature PCB Assembly House offers flexible engagement models tailored to different business strategies and supply chain maturity levels.

Turnkey PCB Assembly: Full Outsourcing, Maximum Convenience

Also known as “one-stop” or “full turnkey,” this model allows customers to provide only design files (Gerber, BOM, pick-and-place), while the PCB Assembly House handles:

- Bare PCB fabrication

- Component sourcing and procurement

- Inventory management

- Assembly and testing

- Final packaging and shipping

This is ideal for:

- Startups and R&D teams lacking purchasing departments.

- Companies entering new markets without established supplier relationships.

- Projects with tight timelines where speed-to-market is critical.

Turnkey reduces overhead and simplifies logistics—but requires trust in the PCB Assembly House's sourcing integrity. Always ask about counterfeit mitigation policies, authorized distributors used, and traceability records.

One major advantage: economies of scale. Large PCB Assembly Houses negotiate better pricing with component vendors, passing savings to clients.

Read our full breakdown of the turnkey PCB assembly process to understand how it streamlines development.

⚠️ Warning: Some low-cost providers claim "turnkey" but source from gray-market channels. Always verify authenticity guarantees.

Consignment (or Partial Consignment): You Control the Components

In this model, the customer provides all or some of the electronic components, and the PCB Assembly House performs only the assembly work.

Use cases include:

- Legacy components no longer available commercially.

- Proprietary or security-sensitive ICs.

- Existing inventory you want to utilize.

- Supply chain disruptions forcing alternative sourcing.

While consignment gives you full control over parts, it shifts inventory risk and logistics burden back to you. You must ensure timely delivery of components to the factory, manage customs clearance (if cross-border), and bear the cost of any damaged or lost parts during transit.

Some PCB Assembly Houses charge higher per-unit fees for consigned jobs due to increased handling complexity and lower automation efficiency.

DFM Checks: Proactive Design Validation Before Production

Regardless of service model, a proactive PCB Assembly House should offer free Design for Manufacturability (DFM) analysis before production begins.

A proper DFM review examines:

- Footprint accuracy against actual component sizes

- Pad spacing and solder mask clearance

- Thermal pad design for BGAs and power components

- Reflow accessibility for double-sided boards

- Panelization strategy and depaneling method

- Test point placement for ICT/FCT

Catching errors early avoids costly respins and delays. For instance, a missing thermal relief on a large ground plane could cause cold solder joints during wave soldering—a flaw easily caught in DFM.

Top-tier PCB Assembly Houses use automated DFM tools combined with expert engineering feedback, delivering actionable reports within hours.

Learn how to optimize your designs with our flexible PCB design best practices guide.

4. Delivery Performance & Responsiveness: Speed Meets Reliability

Time-to-market can make or break a product launch. Whether you’re iterating prototypes or scaling mass production, your PCB Assembly House must deliver predictably and transparently.

Prototype Turnaround: Accelerating Development Cycles

For startups and innovators, rapid prototyping is non-negotiable. Many PCB Assembly Houses now offer express services:

- 24-hour turnaround: Common for simple single-sided SMT boards.

- 48-hour delivery: Feasible for moderately complex double-sided assemblies.

- Next-day shipping options: Including air freight coordination.

Fast prototyping relies on dedicated “quick-turn” lines separate from high-volume production floors. These lines prioritize agility over throughput, allowing faster changeovers and manual interventions when needed.

However, speed shouldn’t compromise quality. Even prototype runs should undergo basic AOI and visual inspection.

Check if the PCB Assembly House offers online quoting and order tracking for prototypes. Real-time status updates reduce uncertainty and improve planning.

Our prototype PCB assembly guide outlines best practices for getting fast, accurate builds.

Mass Production: Stability, Scalability, and On-Time Delivery

Once past validation, transitioning to volume production introduces new challenges:

- Maintaining consistent yield rates across batches

- Managing material shortages or obsolescence

- Controlling labor variability

- Ensuring on-time delivery despite external disruptions

Key metrics to evaluate:

- On-Time Delivery (OTD) Rate: Should exceed 95% for reliable partners.

- First Pass Yield (FPY): Indicates process stability; aim for >98%.

- Scrap/Waste Rate: Lower is better; <2% typical for mature lines.

- Changeover Time: How quickly can they switch between SKUs?

Ask about capacity planning and surge capabilities. Can the PCB Assembly House scale from 1,000 units/month to 50,000+ if demand spikes?

Also consider geographic location. While offshore factories may offer lower costs, nearshore or domestic PCB Assembly Houses provide shorter lead times and easier communication—especially valuable during crises like the global chip shortage.

Transparency and Communication: Seeing Into the Factory

Today’s buyers expect visibility. Leading PCB Assembly Houses offer digital dashboards showing:

- Order receipt confirmation

- Material arrival and inspection status

- Line assignment and start date

- Daily production progress

- Test results and final shipment details

Some even allow video walkthroughs of the production floor or live access to AOI/X-ray images.

Clear communication channels—dedicated account managers, multilingual support, responsive email/chat—are equally important. Misunderstandings in terminology or expectations can derail schedules.

Before signing, test response times. Send a technical question and see how long it takes to get a detailed, accurate reply.

5. Matching Your Project Type to the Right PCB Assembly House

Not all PCB Assembly Houses are suited for every type of project. Understanding your product category helps narrow down the best fit.

For Startups & R&D Teams: Fast, Flexible, Low MOQ

Early-stage companies need agility above all.

Look for:

- No minimum order quantity (MOQ) or very low MOQ (e.g., 1–10 units)

- Rapid prototyping capabilities (<72 hours)

- Free DFM and engineering support

- Transparent pricing with instant online quotes

- Willingness to work iteratively

These “quick-turn” specialists focus on innovation enablement rather than scale. They thrive on frequent design changes and short runs.

Ideal for IoT devices, smart home gadgets, robotics prototypes, and university research projects.

Consider partnering with a PCB Assembly House that understands startup pain points—budget constraints, uncertain timelines, evolving specs.

For Industrial & Medical Devices: High Reliability, Full Traceability

Applications in healthcare, energy, transportation, and industrial automation demand extreme durability and regulatory compliance.

Prioritize:

- ISO 13485 or IATF 16949 certification

- Lot-level traceability (components, operators, equipment IDs)

- Documented process validation (PPAP, FAI)

- Long-term component availability planning

- Lifecycle management support

These PCB Assembly Houses often operate under strict change control procedures. Any modification—even a resistor brand substitution—requires formal approval.

They also maintain detailed records for years, supporting field service, recalls, and audits.

Expect longer lead times and higher costs, justified by mission-critical performance.

For Consumer Electronics: Cost Efficiency at Scale

Mass-market products like smartphones, wearables, audio gear, and appliances live and die by unit cost.

Here, scale matters most.

Choose a PCB Assembly House with:

- Fully automated SMT lines running 24/7

- Strong supply chain partnerships for bulk component discounts

- Lean manufacturing principles (Six Sigma, Kaizen)

- Vertical integration (in-house PCB fabrication + assembly)

- Global logistics networks

Large-scale EMS providers like Foxconn, Jabil, or Sanmina dominate this space. But regional players increasingly compete by offering faster responsiveness and localized support.

Balance cost savings with flexibility. Can they accommodate last-minute firmware updates or minor BOM revisions without halting the line?

Conclusion: Your PCB Assembly House Is a Strategic Partner

Selecting a PCB Assembly House is not merely a procurement decision—it’s a strategic partnership that impacts your product’s quality, time-to-market, scalability, and long-term success.

By focusing on five core pillars—manufacturing capabilities, quality systems, service flexibility, delivery performance, and project alignment—you can identify a partner that grows with you, from prototype to production and beyond.

Whether you're a solo inventor building your first gadget or an enterprise launching a global product line, take the time to assess potential PCB Assembly Houses holistically. Request samples, visit facilities (virtually or in person), and talk to their engineers.

And when you're ready to move forward, don’t hesitate to reach out. If you're looking for a trusted partner with proven expertise in precision assembly, rigorous quality control, and responsive service, contact PCB manufacturer today to discuss your project.

Your next breakthrough starts with the right foundation.