PCB Supply Chain Optimization: How SUNTOP Electronics Delivers Efficiency and Reliability

SUNTOP Electronics

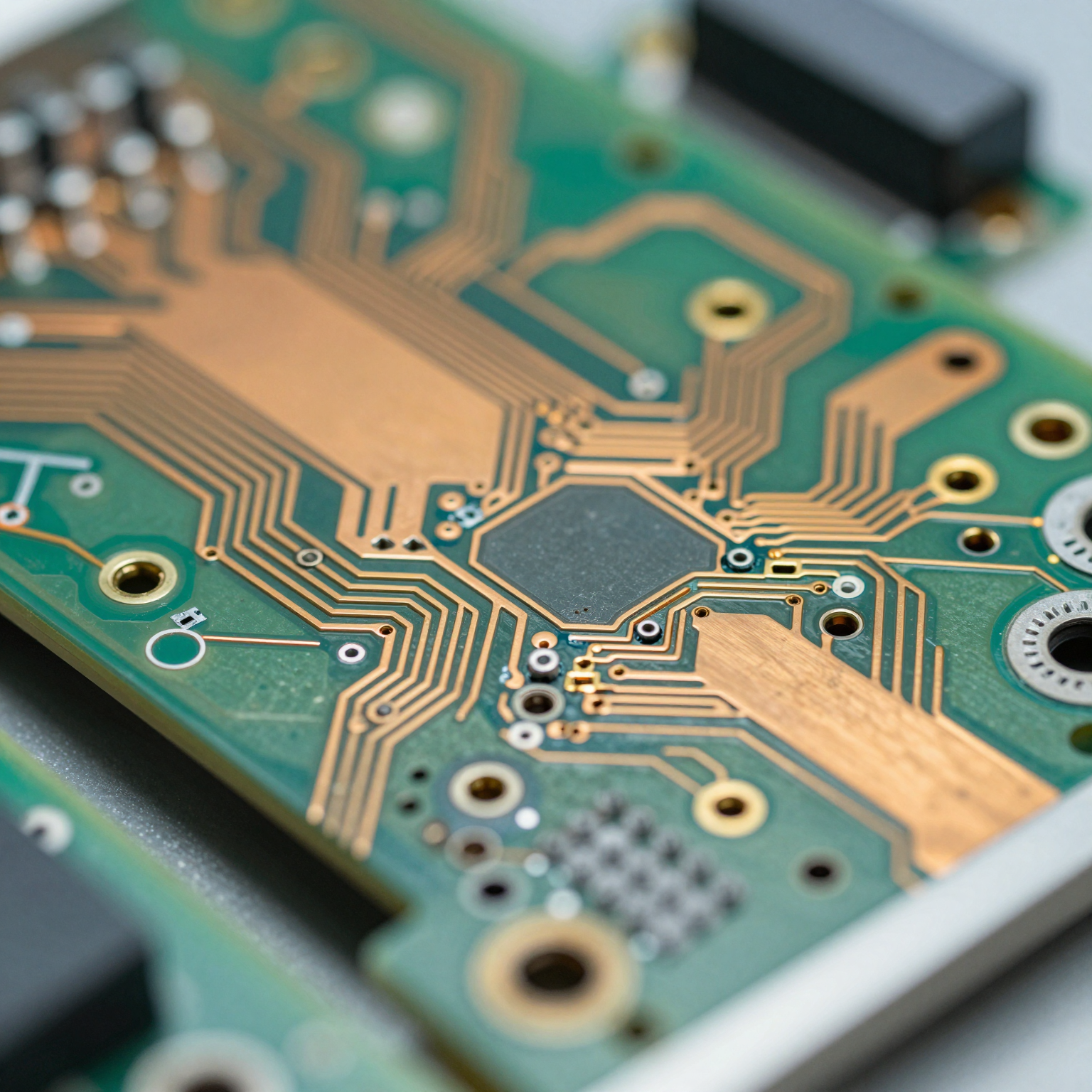

The global electronics industry continues to evolve at a breakneck pace. Manufacturers face unprecedented challenges—volatile component markets, geopolitical disruptions, rising customer expectations for speed and quality, and the relentless push toward miniaturization and smarter devices. At the heart of this ecosystem lies the PCB supply chain, a complex network that, if not optimized, can become a significant bottleneck.

For companies like SUNTOP Electronics—a full-service PCB manufacturer and PCB Assembly service provider—optimizing the entire PCB supply chain isn't just a competitive advantage; it's a necessity for survival and growth. This article explores the key strategies shaping PCB Optimization in 2026 and how integrated providers are leading the charge in delivering resilient, efficient, and high-quality solutions.

Understanding the Modern PCB Supply Chain

The PCB supply chain encompasses every step from raw material procurement to final product delivery. It includes:

- Sourcing of base materials (copper-clad laminates, prepreg, etc.)

- Procurement of electronic components (ICs, resistors, capacitors)

- **PCB fabrication

**

- Component assembly (SMT, through-hole)

- Quality assurance and testing

- Logistics and fulfillment

Each stage is interconnected, meaning a delay or inefficiency in one area can ripple across the entire process. In recent years, supply chain volatility has underscored the need for robustness, transparency, and agility—hallmarks of true PCB Optimization.

Key Challenges in Today’s PCB Supply Chain

Before diving into solutions, it’s essential to understand the hurdles faced by OEMs and contract manufacturers alike.

1. Component Shortages and Lead Time Volatility

Despite some easing since the pandemic peaks, lead times for critical components like microcontrollers, power management ICs, and specialized passives remain unpredictable. Single-source dependencies and limited wafer capacity continue to strain availability.

2. Geopolitical and Logistical Risks

Trade policies, regional conflicts, and shipping disruptions impact both cost and delivery timelines. Manufacturers must now build geographic diversification into their sourcing strategies.

3. Rising Customer Expectations

OEMs demand faster time-to-market, higher reliability, and lower costs—all simultaneously. Meeting these requires seamless coordination between design, procurement, manufacturing, and logistics.

4. Complexity of Advanced Technologies

High-Density Interconnect (HDI) boards, flexible and rigid-flex PCBs, and RF designs require tighter tolerances and more specialized processes, increasing the risk of yield loss and rework if not managed holistically.

How Integrated Providers Enable PCB Supply Chain Optimization

This is where an integrated PCB manufacturer like SUNTOP Electronics shines. By combining PCB fabrication, electronic component sourcing, and PCB assembly services under one roof, we eliminate silos, reduce handoff errors, and accelerate decision-making.

End-to-End Control: From Design to Delivery

One of the most powerful levers for PCB Optimization is vertical integration. When your PCB assembly manufacturer controls both board production and component procurement, you gain:

- Faster turnaround: No waiting for third-party fabricators or assemblers.

- Improved communication: Engineers collaborate across disciplines in real time.

- Better traceability: Full visibility from raw material to finished PCBA.

At SUNTOP, our engineers work closely with clients during the design phase to ensure manufacturability (DFM), reducing costly revisions later. We then leverage our established supplier relationships to secure components efficiently, often using multi-sourcing strategies to mitigate risk

.

Strategic Component Sourcing and Inventory Management

Effective PCB Assembly Optimization hinges on smart parts procurement. Rather than reacting to shortages, proactive manufacturers anticipate them.

We utilize advanced forecasting tools and maintain dynamic relationships with over 200 trusted component suppliers globally. Our dual-sourcing policy ensures that no single component type relies on just one vendor. Additionally, we offer consignment and kitting options, allowing customers to manage inventory while we handle assembly.

For long-lifecycle products, we recommend lifecycle buy strategies—purchasing extended quantities of end-of-life (EOL) components to safeguard future production runs.

Lean Manufacturing and Process Automation

Efficiency begins on the factory floor. At SUNTOP, we’ve invested heavily in automation across our SMT lines, including pick-and-place machines with vision alignment, automated optical inspection (AOI)

, and X-ray systems for BGA inspection.

These technologies not only improve accuracy but also reduce cycle times and labor costs—key metrics in PCB Optimization. Our lean manufacturing principles focus on eliminating waste, improving flow, and continuously refining workflows based on real-time data analytics.

Our 6-step quality control process ensures every board meets stringent standards before shipment, minimizing field failures and returns.

The Role of Digital Transformation in PCB Optimization

In 2026, digital tools are no longer optional—they’re foundational to supply chain resilience.

Real-Time Tracking and Transparency

Customers today expect visibility into their orders. Through our client portal, partners can track project status in real time—from material receipt and production scheduling to testing results and shipping updates.

This level of transparency builds trust and allows for proactive adjustments when issues arise.

AI-Driven Demand Forecasting

Artificial intelligence is transforming how we predict demand and manage inventory. By analyzing historical order patterns, market trends, and even macroeconomic indicators, our systems help us anticipate surges in specific product categories and adjust purchasing accordingly.

While still evolving, AI-powered forecasting reduces overstocking and stockouts, directly contributing to PCB supply chain efficiency.

Cloud-Based Collaboration Platforms

Design files, BOMs, and engineering change orders (ECOs) are now shared securely via cloud platforms. This enables instant collaboration between our teams and clients, regardless of location. Faster approvals mean faster production starts.

Sustainability and Ethical Sourcing: An Emerging Priority

Beyond efficiency, sustainability is becoming a core component of PCB Optimization. Consumers and regulators alike are demanding greener electronics.

SUNTOP is committed to responsible sourcing practices. We audit our suppliers for compliance with environmental standards such as RoHS and REACH. We also prioritize recyclable packaging and energy-efficient manufacturing processes.

By aligning with ethical supply chains, we not only reduce environmental impact but also mitigate reputational and regulatory risks for our clients.

Case Study: Accelerating Medical Device Production

A U.S.-based medical device startup approached SUNTOP with a tight deadline to produce 5,000 units of a portable diagnostic device. The challenge? Several key sensors were facing 20-week lead times.

Instead of halting development, our team leveraged its global sourcing network to identify two alternative, pin-compatible sensors already in stock with pre-vetted suppliers. After validating performance with the client’s engineering team, we redesigned the layout slightly and began production within two weeks.

Thanks to our integrated PCB assembly services and rapid response, the client launched on schedule—six weeks ahead of competitors who relied on fragmented supply chains.

This example illustrates how true PCB Assembly Optimization goes beyond cost-cutting; it’s about enabling innovation through agility.

Looking Ahead: The Future of PCB Supply Chain Resilience

As we move deeper into 2026, several trends will shape the next generation of PCB Optimization:

- Nearshoring and Regional Hubs: More companies are shifting production closer to end markets to reduce transit times and exposure to international disruptions.

- Blockchain for Traceability: While still nascent, blockchain technology promises immutable records of component provenance, enhancing counterfeit prevention.

- Modular Design Strategies: Standardizing sub-assemblies allows for easier swaps during component shortages without redesigning entire systems.

At SUNTOP, we're actively exploring these innovations to further strengthen our PCB supply chain capabilities.

Why Partner with an Integrated PCB Manufacturer?

Choosing a partner that offers both PCB fabrication and comprehensive PCB assembly services provides tangible benefits:

- Single Point of Accountability: One team owns the outcome, reducing finger-pointing between vendors.

- Faster Problem Resolution: Issues are resolved internally, without external coordination delays.

- Cost Efficiency: Reduced logistics, fewer intermediaries, and optimized workflows lower total cost of ownership.

Whether you're developing consumer electronics, industrial controls, or life-saving medical equipment, having a reliable, agile partner makes all the difference.

Get Started with Optimized PCB Production

Ready to streamline your electronics manufacturing? Discover how SUNTOP Electronics can help you achieve faster time-to-market, improved quality, and greater supply chain resilience.

Explore our full range of PCB manufacturing capabilities and learn more about what sets us apart as a trusted about PCB assembly company. For immediate assistance, contact PCB manufacturer directly to discuss your project needs or get a PCB quote today.