PCB Board Assembly: PCB, FPC, HDI, and Rigid-Flex Assembly Technologies

Rachel Roland

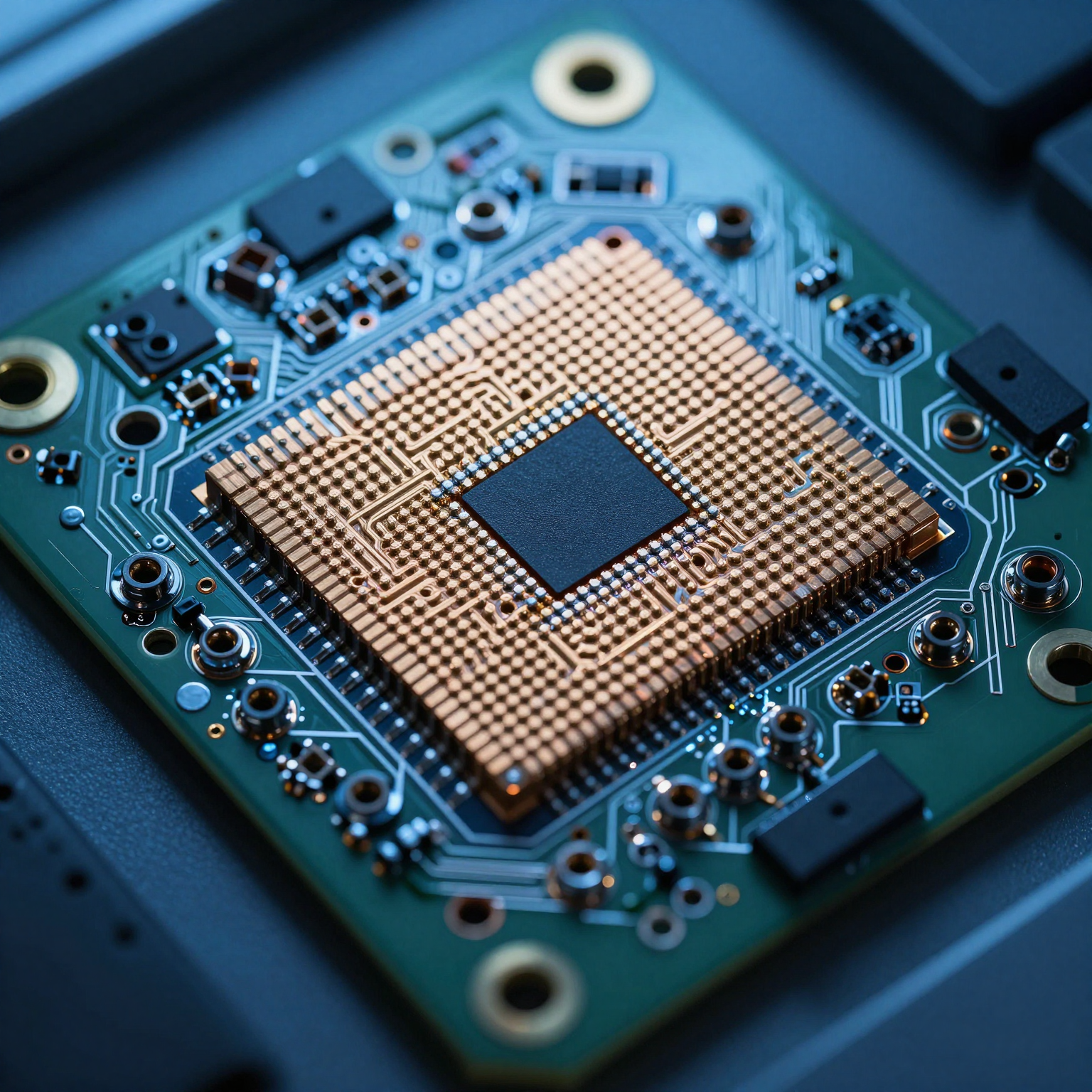

Understanding PCB Board Assembly: The Heart of Modern Electronics

In today’s technology-driven world, the Printed Circuit Board (PCB) serves as the backbone of virtually every electronic device. From smartphones and medical devices to automotive systems and aerospace equipment, PCBs enable functionality by interconnecting electronic components. However, designing a PCB is only half the story — the real magic happens during PCB board Assembly, where raw boards are transformed into fully functional units ready for integration.

PCB board Assembly refers to the process of mounting and soldering electronic components onto a bare printed circuit board. This critical phase determines not only the performance but also the reliability and longevity of the final product. As electronics continue to shrink in size while increasing in complexity, advanced assembly techniques such as FPC Assembly, HDI Assembly, and Rigid-Flex PCB Assembly have become essential in meeting modern design demands.

This article explores these cutting-edge assembly methods, their unique benefits, applications, and what sets them apart in the evolving landscape of electronic manufacturing.

What Is PCB Board Assembly?

At its core, PCB board Assembly involves placing components like resistors, capacitors, integrated circuits (ICs), and connectors onto a fabricated PCB and securing them using soldering processes. There are two primary methods used:

- Surface Mount Technology (SMT): Components are mounted directly onto the surface of the PCB.

- Through-Hole Technology (THT): Leads of components are inserted into drilled holes and soldered on the opposite side.

While both methods remain relevant, SMT dominates modern production due to its ability to support miniaturization and high-density designs. The choice of assembly method depends on factors such as component type, board complexity, environmental conditions, and intended application.

Advanced forms of PCB board Assembly go beyond traditional rigid boards and include flexible, high-density, and hybrid configurations that offer greater design freedom and performance optimization.

FPC Assembly: Enabling Flexibility in Design

What Is FPC Assembly?

FPC Assembly, or Flexible Printed Circuit Assembly, involves assembling components onto flexible substrate materials like polyimide or polyester. Unlike rigid PCBs, FPCs can bend, twist, and conform to compact or irregularly shaped spaces, making them ideal for wearable devices, foldable electronics, and space-constrained applications.

The flexibility of FPCs reduces the need for bulky wiring harnesses and connectors, improving signal integrity and reducing weight — a crucial advantage in industries like aerospace and medical devices.

Key Benefits of FPC Assembly

- Space Efficiency: Ideal for ultra-thin and compact devices.

- Durability: Resistant to vibration and thermal stress.

- Weight Reduction: Lighter than traditional rigid boards.

- Improved Reliability: Fewer interconnects mean fewer failure points.

Applications range from consumer electronics (smartwatches, cameras) to industrial sensors and implantable medical devices. When done correctly, FPC Assembly ensures consistent electrical performance even under dynamic bending conditions.

For best results, manufacturers must account for material handling challenges, precise alignment during component placement, and specialized reflow profiles to avoid damaging the flexible substrate.

To learn more about best practices in flexible circuit design, check out our guide on flexible PCB design best practices.

HDI Assembly: Powering High-Density Interconnects

What Is HDI Assembly?

HDI Assembly stands for High-Density Interconnect Assembly, a technique used to create PCBs with finer lines and spaces, smaller vias (microvias), and higher connection pad density than conventional PCBs. HDI technology enables more functionality in smaller footprints, which is vital for next-generation mobile devices, IoT gadgets, and advanced computing systems.

An HDI PCB typically uses microvias, blind/buried vias, and sequential lamination layers to achieve complex routing in minimal space. These features demand precision during HDI Assembly, especially when dealing with tight tolerances and sensitive components like Ball Grid Arrays (BGAs) and chip-scale packages (CSPs).

Advantages of HDI Assembly

- Miniaturization: Enables smaller devices without sacrificing performance.

- Enhanced Signal Integrity: Shorter signal paths reduce electromagnetic interference (EMI) and improve speed.

- Higher Reliability: Microvia structures provide robust interlayer connections.

- Better Thermal Management: Efficient heat dissipation through optimized layer stacking.

Because of these advantages, HDI Assembly is widely adopted in smartphones, tablets, military communication systems, and high-speed servers.

Manufacturers must employ advanced equipment such as laser drilling machines, automated optical inspection (AOI), and X-ray inspection systems to ensure quality during HDI Assembly. Additionally, strict control over solder paste printing and reflow soldering parameters is essential to prevent defects in densely packed layouts.

Stay updated on emerging trends with our analysis of HDI PCB technology trends.

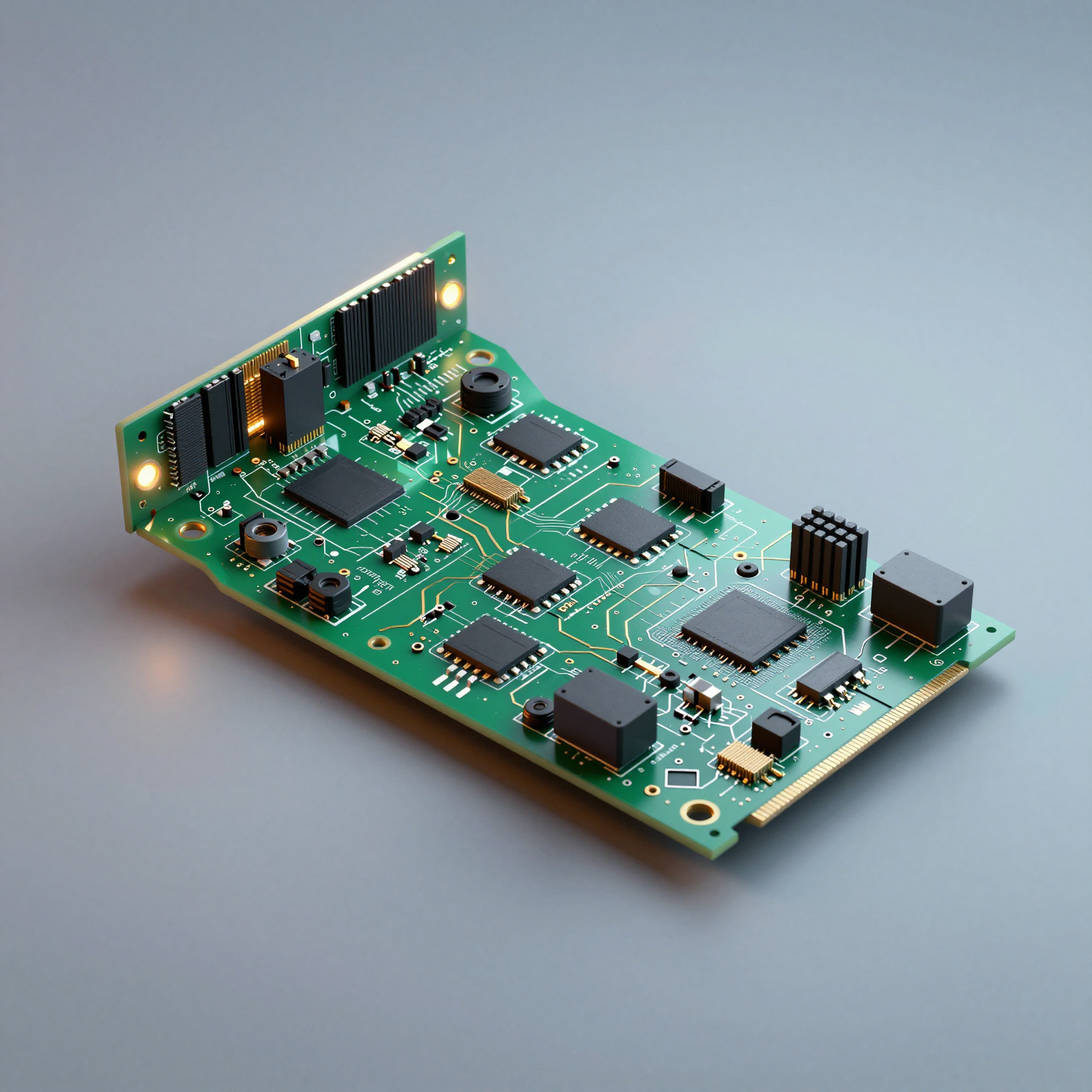

Rigid-Flex PCB Assembly: Merging Strength and Flexibility

What Is Rigid-Flex PCB Assembly?

Rigid-Flex PCB Assembly combines the structural stability of rigid boards with the adaptability of flexible circuits in a single integrated unit. These hybrid assemblies consist of multiple layers of flexible circuit substrates attached to rigid boards, allowing 3D packaging and eliminating the need for connectors and cables.

This integration improves system reliability by reducing interconnection points — a common source of failure in harsh environments.

Why Choose Rigid-Flex PCB Assembly?

- Superior Reliability: Fewer solder joints and connectors increase durability.

- Space and Weight Savings: Eliminates separate flex cables and connectors.

- Design Freedom: Supports complex 3D configurations ideal for compact enclosures.

- High Performance: Maintains signal integrity across transitions between rigid and flexible sections.

Industries such as aerospace, defense, robotics, and medical instrumentation rely heavily on Rigid-Flex PCB Assembly for mission-critical applications where failure is not an option.

However, this sophistication comes with increased manufacturing complexity. Proper stack-up design, impedance control, and careful handling during assembly are crucial. Specialized fixtures may be required to support flexible areas during component placement and reflow.

Despite higher initial costs, the long-term benefits in terms of reduced assembly time, improved reliability, and enhanced performance make Rigid-Flex PCB Assembly a smart investment for demanding applications.

Choosing the Right PCB Assembly Partner

Selecting a capable and experienced PCB assembly manufacturer is critical when working with advanced technologies like FPC, HDI, and Rigid-Flex. Not all facilities possess the equipment, expertise, or quality systems needed to handle these sophisticated processes.

Key considerations when evaluating a partner include:

- Technical Capabilities: Do they offer SMT, THT, BGA, and fine-pitch assembly?

- Equipment & Automation: Are they equipped with pick-and-place machines, reflow ovens, AOI, and X-ray inspection?

- Quality Certifications: Look for ISO 9001, IPC-A-610, and UL certifications.

- Testing Services: In-circuit testing (ICT), functional testing (FCT), and boundary scan should be available.

- Turnaround Time: Can they support rapid prototyping and volume production?

A reliable provider will also offer comprehensive services such as design for manufacturability (DFM) reviews, component sourcing, and full turnkey solutions.

If you're looking for expert guidance or want to discuss your project requirements, consider reaching out to a trusted partner. You can contact PCB manufacturer directly to get personalized support and request a quote tailored to your needs.

Applications Across Industries

Advanced PCB board Assembly techniques are transforming numerous sectors:

- Consumer Electronics: Smartphones use HDI Assembly; wearables depend on FPC Assembly.

- Medical Devices: Implantables and diagnostic tools benefit from Rigid-Flex PCB Assembly.

- Automotive: Advanced driver-assistance systems (ADAS) and infotainment rely on high-reliability assemblies.

- Aerospace & Defense: Mission-critical avionics require rugged, lightweight, and highly reliable Rigid-Flex and HDI solutions.

- Industrial Automation: Robotics and control systems utilize durable FPCs and HDI boards for compact, high-performance operation.

Each industry imposes unique demands — temperature resistance, shock tolerance, EMI shielding, or long-term reliability — making customized PCB board Assembly strategies essential.

Future Trends in PCB Board Assembly

As electronic devices evolve, so too do the methods and materials used in PCB board Assembly. Emerging trends include:

- Ultra-Fine Pitch Components: Driving demand for more precise placement systems.

- Embedded Components: Placing passive or active components within the PCB layers themselves.

- Advanced Materials: Use of low-loss dielectrics and thermally conductive substrates.

- AI in Manufacturing: Predictive analytics for defect detection and process optimization.

- Sustainable Practices: Lead-free soldering, recyclable materials, and energy-efficient processes.

Additionally, the convergence of FPC Assembly, HDI Assembly, and Rigid-Flex PCB Assembly in modular designs points toward increasingly integrated and intelligent electronic systems.

Manufacturers who invest in innovation, automation, and workforce training will lead the next wave of advancements in PCB board Assembly.

Conclusion: Building the Future One Board at a Time

PCB board Assembly is no longer just about attaching components — it's about enabling technological breakthroughs across industries. Whether through the flexibility of FPC Assembly, the density of HDI Assembly, or the hybrid strength of Rigid-Flex PCB Assembly, each method plays a pivotal role in shaping the future of electronics.

Choosing the right technology and manufacturing partner ensures your product meets performance, reliability, and scalability goals. With rapid innovation and growing demand for smarter, smaller, and more powerful devices, mastering advanced PCB assembly techniques has never been more important.

To explore how professional PCB assembly services can bring your next project to life, visit our detailed overview of available capabilities and industry applications.